The cable runs in a structured cabling environment terminate in a punch-down block, which is usually a 66-block or a 110-block, or BIX- or Krone-style blocks, “Cabling System Connections and Termination.” The 110-block is most commonly used for voice and data cabling termination, although you will find many installations that use a 110-block for termination voice systems and patch panel for terminating data systems. Punch-down block termination provides a cross-connect from one cable set to another, allowing for easier moves, adds, and changes (MACs) as the need arises.

What Is A Punch-Down Block?

A punch-down block is mounted to a backboard, which is usually made of plywood and secured to the wall of a TC. If you install cabling on more than the floor, each floor must have a separate punch-down block with terminations for the cable drops from the higher floors. Backbone cables should be installed with 10-foot service coils at the termination points, which are commonly located on the backboard in the closet. Figure 1 illustrates a typical TC.

Install patch cables from the punch-down block to a patch panel. The purpose of the patch panel is to connect the backbone system to networking equipment such as a hub or router. End-user equipment, which includes workstations, network printers and scanners, and other shared electronic equipment, generally connect to a hub (also called a concentrator) or router via RJ-45 cable jacks or outlets.

There are pros and cons to using cross-connect blocks. They offer higher densities and require less space than patch panels, and also are less expensive. On the other hand, they are the least friendly for making moves, adds, and changes to the configuration. Skill is involved in removing and rea-ranging cables. When using patch panels, almost anyone can rearrange the system. In both situations security, ease of attachment, expense, and physical space are all considerations.

What Is Fiber Optic Patch Panel?

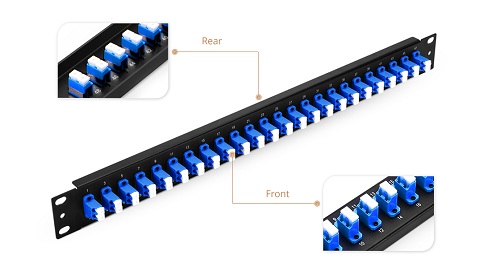

Fiber optic patch panel is commonly used in fiber optic management unit. When you install and manage the fiber optic links, you may encounter hundreds or even thousands of fiber optic cables and cable connections, fiber optic management products are used to offer space and protection for the fiber cables and cable links, and they make it easier for the cable management and troubleshoot work. Our fiber optic patch panels are all sliding type, they are compatible to use with equipment and cable assembly products from other companies. Now you can see the two products from our store. They are SC fiber patch panel, 24 Port Fiber Patch Panel.

12 port OS1/2 9μm Duplex Plastic SC Fiber Patch Panel

Features of FS001 SERIES MOLDED

● Compatible with Leviton fiber adapter panels

● Adapter panels offered in LC, SC, ST, and blank styles, fit for all Opt-X rack-mount and wall-mount enclosures and VertiGO® panels

● Equipped with plastic dust caps to make connecting panels tool-free and efficient

● Integrated couplers eliminate “rattle” and loose fit

● Captive push-lock pins allow for quick tool-less installationCaptive push-lock pins allow for quick tool-less installation

● Exceeds optical performance standards and meets all other applicable standards

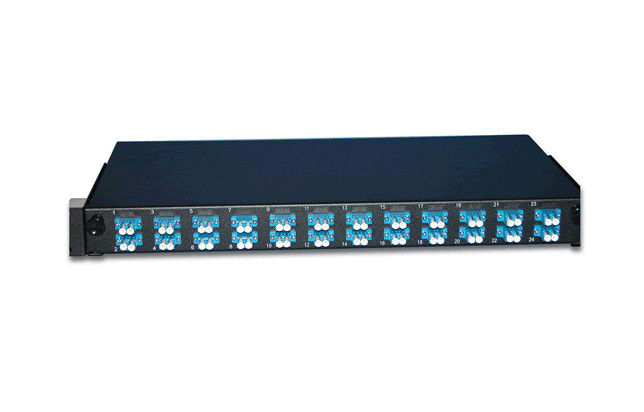

12 pack LC Duplex 24 Port Fiber Patch Panel Blue

● Compatible with BlackBox Fiber Adapter Panel

● Adapter panels snap easily into all standard fiber enclosures, cabinets, and patch panels, including all Black Box® models.

● High-density panels with ST or LC connectors are available.

● The easy way to patch fiber cables to termination enclosures

We supply many fiber optic patch panels. They are with types to fit from 12 fibers to 72 fiber management demand. These fiber optic patch panels are with optional various kinds of fiber optic adapters and fiber optic pigtails, types including SC, LC, ST, FC, MU, E2000, etc. We have a number of different customizable options available to fit whatever application you require. With products compatible with trusted brands including Black Box, Wirewerks, Mr-technologies, Corning, Leviton, Panduit Opticom adapter panel and more.