Local area network (LAN) campus and building backbones, as well as data center backbones, are migrating to higher cabled fiber counts to meet increasing system bandwidth needs. Ribbon optical cables are now being deployed to meet this need, as they provide the highest fiber density relative to cable size, maximize utilization of pathway and spaces and facilitate ease of termination. This article may provide some knowledge of ribbon optical cable.

Ribbon Optical Cable Design

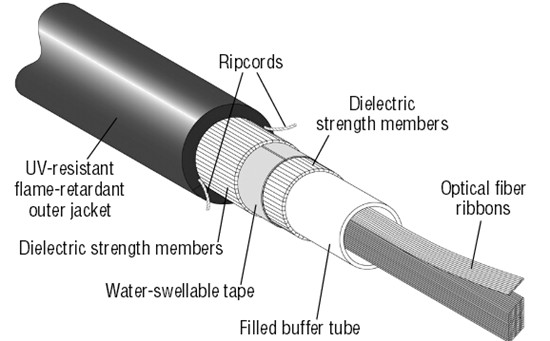

Ribbon optical cable is now being widely used in campus, building and data center backbone applications where fiber counts of more than 24 are required. This kind of fiber optic cable offers robust performance equivalent to the stranded loose tube cable. It provides the maximum fiber density relative to cable diameter when compared to stranded loose tube and tight-buffered cable designs. The cable design characteristically consists of 12 to 216 fibers organized inside a central tube. There are two kinds of jacket material for ribbon optical cable. Non-flame-retardant jacket material is often used in outdoor applications while flame-retardant outer jackets are used for indoor applications. Picture below shows a basic construction of ribbon optical cable.

MTP Connector Makes a Easy Ribbon Optical Cable Termination

For many years, people have been reluctant to use ribbon optical cable in the LAN and data center because 12-fiber ribbon fiber optic cable field terminations were limited. With the introduction of field-installable 12-fiber array connectors, 12-fiber ribbons are easily terminated with simplex and duplex connectors such as LC or SC connectors or with the MTP connector. The MTP connector (shown in the picture below) is a 12-fiber push/pull optical connector with a foot-print similar to the SC simplex connector. These high-density connectors are used to significantly accelerate the network cabling process, minimize errors and reduce congestion in patch panels.

Today, the MTP connector is commonly available in preterminated form—as a pigtail to be spliced onto a 12-fiber ribbon, or as a MTP patch cord which is terminated on each end (shown in the picture below). Many end-users are now using preterminated cables where the cable is factory terminated with MTP connectors and/or simplex or duplex connectors to ensure the highest quality connector insertion loss and return loss performance and to expedite the cable installation.

Ribbon Optical Cable Greatly Saves the Pathway and Spaces

Optimal cabled fiber density in data-center pathway and spaces is important to facilitate efficient cooling systems as well as for removal of abandoned cable in accordance, so it’s essential to maximize use of pathway and spaces. Ribbon fiber cables offer up to 45 percent space savings, and three times the fiber-tray capacity over traditional bulkier cable solutions. At the same time, it also minimizes the cable tray weight.

Conclusion

Because the ribbon optical cable offers the highest fiber packing density to maximize pathway and space utilization in ducts and raceways as well as patch panels, it is now being deployed in areas where stranded loose tube and tight-buffered cable have historically been used. Fiberstore provide all kinds of ribbon optical cables (12 to 216 fibers) and MTP connectors, as well as MTP truck patch cables with low price and high quality. For more information, please visit www.fs.com.