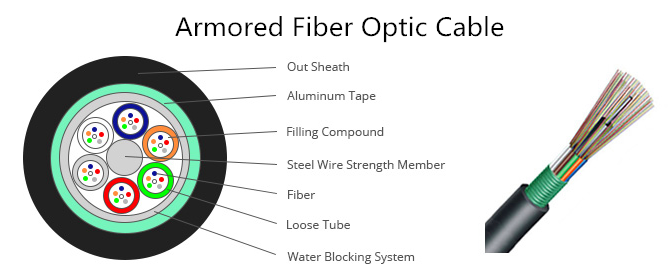

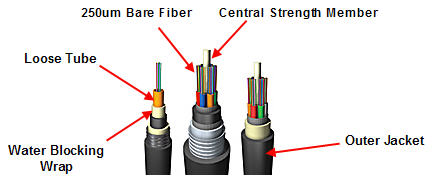

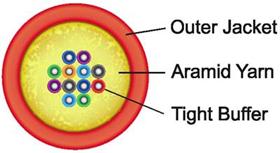

Fiber optic cable is available in many physical variations, such as single and multiple conductor constructions, aerial and direct burial styles, plenum and riser cables, etc. But there are two basic styles of fiber optic cable construction: loose tube fiber and tight buffered fiber. From the picture below, we can see that loose tube fiber holds more than one optical fiber, each individually sleeved core is bundled loosely within an all-encompassing outer jacket. However, in tight buffered cables, there are not so many cables as loose tube fibers.

Loose Tube Fiber

Loose tube fibers are designed for harsh environmental conditions in the outdoors. In loose tube cables, the coated fiber “floats” within a rugged, abrasion resistant, oversized tube which is filled with optical gel. Since the tube does not have direct contact with the fiber, any cable material expansion or contraction will not cause stress on the fiber. This gel also helps protect the fibers from moisture, making the cables ideal for high humidity environments. Cable containing loose buffer-tube fiber is generally very tolerant of axial forces of the type encountered when pulling through conduits or where constant mechanical stress is present such as cables employed for aerial use. Since the fiber is not under any significant strain, loose buffer-tube cables exhibit low optical attenuation losses. Although loose-tube gel-filled fiber optic cables are used for high-fiber-count, long-distance telco applications, they are an inferior design for the Local Area Network applications where reliability, attenuation stability over a wide temperature range and low installed cost are the priorities.

Tight Buffered Cable

Tight buffered cables, in contrast, are optimized for indoor applications. In the tight buffer construction, instead of using the gel layer loose tube cable has, it uses a two-layer coating. One is plastic and the other is waterproof acrylate. So tight buffered cables may be easier to install, because there is no gel to clean up and it does not require a fan out kit for splicing or termination. Because the fiber is not free to “float” however, tensile strength is not as great. Tight buffer cable is normally lighter in weight and more flexible than loose-tube cable and is usually employed for less severe applications. Such applications include moderate distance transmission for telco local loop, LAN, SAN, and point-to-point links in cities, buildings, factories, office parks and on campuses. Tight-buffered cables offer the flexibility, direct connectability and design versatility necessary to satisfy the diverse requirements existing in high performance fiber optic applications.

Each construction has inherent advantages. The loose buffer tube offers lower cable attenuation from microbending in any given fiber, plus a high level of isolation from external forces. Under continuous mechanical stress, the loose tube permits more stable transmission characteristics. The tight buffer construction permits smaller, lighter weight designs for similar fiber configuration, and generally yields a more flexible, crush resistant cable. So, you should choose the appropriate cable for your applications. Fiberstore offers both loose tube and tight buffer cables with high quality and low price. It may be your optimal choice to buy optic products.

Related article: