Fiber optic cables are the medium of choice in tele communications infrastructure, enabling the transmission of high-speed voice, video, and data traffic in enterprise and service provider networks. Depending on the type of application and the reach to be achieved, various types of fiber may be considered and deployed.

Multimode vs. Single-Mode Cable

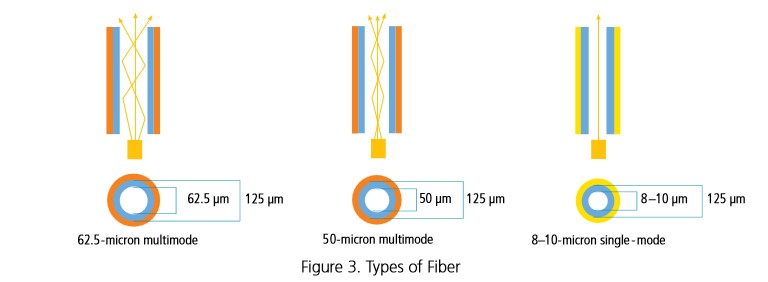

Multimode cable has a large-diameter core and multiple pathways of light. The two most commnon are 50 micron and 62.5 micron.

Multimode fiber optic cable can be used for most general data and voice fiber applications, such as bringing fiber to the desktop, adding segments to an existing network, and in smaller applications such as alarm systems. Both 50- and 62.5-micron cable feature the same cladding diameter of 125 microns, but 50-micron fiber cable features a smaller core (the light-carrying portion of the fiber). Also, both also use either LED or laser light sources.

Although both can be used in the same way, 50-micron cable is recommended for premise applications (backbone, horizontal,and intrabuilding connections) and should be considered for any new construction and installations. The big difference between the two is that 50-micron cable provides longer link lengths and/or higher speeds, particularly in the 850-nm wavelength. 50 micron OM4 fiber optic cable now save up to 30% off sale in our store, if have interest, search Fiberstore on google.

Single-mode cable has a small 8–10-micron glass core and only one pathway of light. With only a single wavelength of light passing through its core, single-mode cable realigns the light toward the center of the core instead of simply bouncing it off the edge of the core as multimode does.

Single-mode cable provides 50 times more distance than multimode cable does. Consequently, single-mode cable is typically used in high-bandwidth applications and in long-haul network connections spread out over extended areas, including cable television and campus backbone applications. Telcos use it for connections between switching offices. Single-mode cable also provides higher bandwidth, so you can use a pair of single-mode fiber strands full-duplex for up to twice the throughput of multimode fiber.

Simplex vs. duplex Patch cables

Multimode and single-mode patch cables can be simplex or duplex.

Simplex has one fiber, while duplex zipcord has two fibers joined with a thin web. Simplex (also known as single strand) and duplex zipcord cables are tight-buffered and jacketed, with Kevlar strength members. Because simplex fiber optic cable consists of only one fiber link, you should use it for applications that only require one-way data transfer. For instance, an interstate trucking scale that sends the wieght of the truck to a monitoring station or an oil line monitor that sends data about oil flow to a central location.

Use duplex multimode or single-mode fiber optic cable for applications that require simultaneous, bidirectional data transfer. Workstations, fiber switches and servers, Ethernet switches, backbone ports, and similar hardware require duplex cable.

Indoor/Outdoor Cable

Indoor/outdoor cable uses dry-block technology to seal ruptures against moisture seepage and gel-filled buffer tubes to halt moisture migration. Comprised of a ripcord, core binder, a flame-retardant layer, overcoat, aramid yarn, and an outer jacket, it is designed for aerial, duct, tray, and riser applications.

PVC (Riser) vs. Plenum-Rated

PVC cable (also called riser-rated cable even though not all PVC cable is riser-rated) features an outer polyvinyl chloride jacket that gives off toxic fumes when it burns. It can be used for horizontal and vertical runs, but only if the building features a contained ventilation system. Plenum can replace riser, but riser cannot be used in plenum spaces.

“Riser-rated” means that the jacket contains PVC. The cable carries a CMR (communications riser) rating and is not for use in plenums.

Distribution-Style vs. Breakout-Style

Distribution-style cables have several tight-buffered fibers bundled under the same jacket with Kevlar or fiberglass rod reinforcement.These cables are small in size and are used for short, dry conduit runs, in either riser or plenum applications. The fibers can be directly terminated, but because the fibers are not individually reinforced, these cables need to be broken out with a “breakout box” or terminated inside a patch panel or junction box.

Breakout-style cables are made of several simplex cables bundled together, making a strong design that is larger than distribution cables. Breakout cables are suitable for conduit runs and riser and plenum applications. Fiberstore supply high quality Multi-purpose Breakout Cables which facilitates easy installation of fiber-optic connectors. Buy Bulk Fiber Optic Cable on our worldwide online store with your confidence.

Loose-Tube vs. Tight-Buffered Fiber Optic Cable

There are two styles of fiber optic cable construction: loose tube and tight buffered. Both contain some type of strengthening member, such as aramid yarn, stainless steel wire strands, or even gel-filled sleeves. But each is designed for very different environments.

Loose-tube cable is specifically designed for harsh outdoor environments. It protects the fiber core, cladding, and coating by enclosing everything within semi-rigid protective sleeves or tubes. Many loose-tube cables also have a water-resistant gel that surrounds the fibers. This gel helps protect them from moisture, which makes loose-tube cable great for harsh, high-humidity environments where water or condensation can be a problem. The gel-filled tubes can also expand and contract with temperature changes. There are many fiber cable types of loose tube, for example, ADSS Cable is used by electrical utility companies as a communications medium.

But gel-filled loose-tube cable is not the best choice when cable needs to be routed around multiple bends, which is often true in indoor applications. Excess cable strain can force fibers to emerge from the gel.

Tight-buffered cable, in contrast, is optimized for indoor applications. Because it’s sturdier than loose-tube cable, it’s best suited for moderate-length LAN/WAN connections or long indoor runs. It’s easier to install, as well, because there’s no messy gel to clean up and it doesn’t require a fan-out kit for splicing or termination. You can install connectors directly to each fiber.