Based on 900um tight buffered fiber and 250um coated fiber there are two basic types of fiber optic cable constructions – Tight Buffered Cable and Loose Tube Cable.

Loose Buffer

A loose buffer’s inner diameter is much larger than a fiber’s outer diameter. Two major advantages from this design are perfect fiber isolation from mechanical forces (within given range) and protection from moisture. The first advantage is due to mechanical dead zone. A force imposed on a buffer does not affect the fiber until this force becomes large enough to straighten the fiber inside the buffer. A loose buffer can be easily filled with a water-blocking gel, which provides its second advantage. In addition, a loose buffer can accommodate several fibers, thus reducing the cost of the cable. On the other hand, this type of cable cannot be installed vertiacally and its end preparation for connectorization (splicing and termination) is labour-intensive. Conseuqently, the loose buffer type of cable is used mostly in outdoor installations because it provides stable and reliable transmission over a wide range of temperatures, mechanical stress, and other environment conditions.

Loose tube structure isolates the fibers from the cable structure. This is a big advantage in handling thermal and other stresses encountered outdoors, which is why most loose tube fiber optic cables are built for outdoor applications. In outside application, ADSS Cable is the special loose tube cable.

Loose-tube cables typically are used for outside-plant installation in aerial, duct and direct-buried applications.

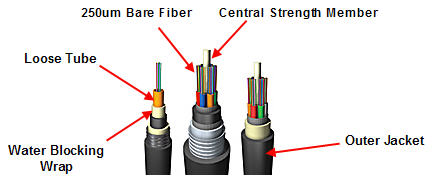

Structure of a Loose Tube Cable

Elements in a loose tube fiber optic cable:

1. Multiple 250um coated bare fibers (in loose tube)

2. One or more loose tubes holding 250um bare fibers. Loose tubes strand around the central strength member.

3. Moisture blocking gel in each loose tube for water blocking and protection of 250um fibers

4. Central strength member (in the center of the cable and is stranded around by loose tubes)

5. Aramid Yarn as strength member

6. Ripcord (for easy removal of outer jacket)

7. Outer jacket (Polyethylene is most common for outdoor cables because of its moisture resistant, abrasion resistant and stable over wide temperature range characteristics. )

Tight Buffer

A tight buffer’s inner diameter is equal to the fiber’s coating diameter, as illustrated in Figure 2.33. Its primary advantage is ists ability to keep the cable operational despite a break in the fiber. Since a buffer holds a fiber firmly, a small separation of the fiber ends won’t interrupt the service completely, althought it will definitely degrade signal quality. That is why the military was the first customer and still is the largest for this type of fiber cable. A tight buffer is rugeed, allowing a smaller bend radius. Since each buffer contains only one fiber and there is no gel to be removed, it is easy to prepare this cable for connectorization. Cables having a tight buffer can be installed vertically. In general, tight buffer cables are more sensitive to temperature, mechanical and water impacts than the loose buffer cables; hence, they are recommended mostly for indoor applications. On the other hand, tight buffer cables designed for special applications (such as military and undersea are the strongest cable available.

Tight buffered cables are mostly built for indoor applications, although some tight buffered cables have been built for outdoor applications too. Here we recommend you a good site to buy fiber optic cable, fiberstore is a fantastic selection of fiber optic cable, including simplex,duplex,tight buffered,breakout, breakout, plastic fiber optic cable etc. More information want to know, search fiberstore on Google.

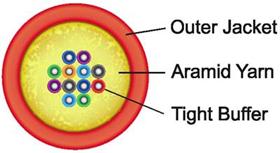

Structure of a Tight Buffered Cable

Elements in a tight buffered fiber optic cable

1. Multiple 900um tight buffered fibers (stranded around the central strength member)

2. Central strength member (in the center of the cable)

3. Aramid Yarn (trade name Kevlar, Kevlar was developed by Dupont) (wrapped around the fibers, for physical protection and cable pulling)

4. Ripcord (for easy removal of outer jacket)

5. Outer jacket (also called sheath, PVC is most common for indoor cables because of its flexible, fire-retardant and easy extrusion characteristics. )

Fiberstore specializes in fiber optic cable assemblies and fiber optic network devices manufacturing, we are known as the fiber optic cable manufacturer for the excellent products quality, competitive prices, fast delivery and good service. We not only offer bulk fiber optic cable assemblies to some world leading companies in this industry, but we also cooperate with many other companies from all over the world and support these partners to win in the market. We are professional China fiber optic company.