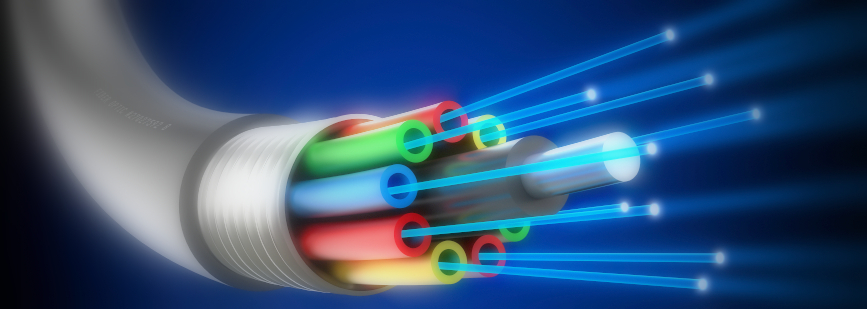

What are the fiber optic cable advantages and disadvantages? An optical fiber or fiber optic cable is a flexible, transparent fiber made by drawing glass, which are used most often as a means to transmit light between the two ends of the fiber and find wide usage in fiber-optic communications, where they permit transmission over longer distances and at higher bandwidths (data rates) than wire cables. Whether should I use optical fiber cables in my network? Single mode fiber or multimode fiber? Don’t worry, read through this post to learn both fiber optic cable advantages and disadvantages and then make a right choice.

Fiber Optic Cable Advantages and Disadvantages

- Bandwidth

Fiber optic cables have a much greater bandwidth than metal cables. The amount of information that can be transmitted per unit time of fiber over other transmission media is its most significant advantage.

- Low Power Loss

An optical fiber offers low power loss, which allows for longer transmission distances. In comparison to copper, in a network, the longest recommended copper distance is 100m while with fiber, it is 2km.

- Interference

Fiber optic cables are immune to electromagnetic interference. It can also be run in electrically noisy environments without concern as electrical noise will not affect fiber.

- Size

In comparison to copper, a fiber optic cable has nearly 4.5 times as much capacity as the wire cable has and a cross sectional area that is 30 times less.

- Weight

Fiber optic cables are much thinner and lighter than metal wires. They also occupy less space with cables of the same information capacity. Lighter weight makes fiber easier to install.

- Security

Optical fibers are difficult to tap. As they do not radiate electromagnetic energy, emissions cannot be intercepted. As physically tapping the fiber takes great skill to do undetected, fiber is the most secure medium available for carrying sensitive data.

- Flexibility

An optical fiber has greater tensile strength than copper or steel fibers of the same diameter. It is flexible, bends easily and resists most corrosive elements that attack copper cable.

- Cost

The raw materials for glass are plentiful, unlike copper. This means glass can be made more cheaply than copper.

- Difficult to Splice

The optical fibers are difficult to splice, and there are loss of the light in the fiber due to scattering. They have limited physical arc of cables. If you bend them too much, they will break.

- Expensive to Install

The optical fibers are more expensive to install, and they have to be installed by the specialists. They are not as robust as the wires. Special test equipment is often required to the optical fiber.

- Highly Susceptible

The fiber optic cable is a small and compact cable, and it is highly susceptible to becoming cut or damaged during installation or construction activities. The fiber optic cables can provide tremendous data transmission capabilities. So, when the fiber optic cabling is chosen as the transmission medium, it is necessary to address restoration, backup and survivability.

- Can’t Be Curved

The transmission on the optical fiber requires repeating at distance intervals. The fibers can be broken or have transmission losses when wrapped around curves of only a few centimeters radius.

Conclusion

Fiber optic cable has both advantages and disadvantages. However, in the long run, optical fiber will replace copper. In today’s network, fiber optic cable becomes more popular than before and is widely used. FS.COM, as a leading optics supplier, provides all kinds of optical fiber cables with high quality and low price for your option.

Related Article: What Are the Most Popular Fiber Optic Cable Types?

Related Article: What Kind of Fiber Patch Cord Should I Choose?

G.657 optical fibers are intended to be compatible with the G.652 optical fibers but have differing bend sensitivity performance. It is designed to allow fibers to bend, without affecting performance. This is achieved through an optical trench that reflects stray light back into the core, rather than it being lost in the cladding, enabling greater bending of the fiber. As we all know, in cable TV and FTTH industries, it is hard to control bend radius in the field. G.657 is the latest standard for FTTH applications, and, along with G.652 is the most commonly used in last drop fiber networks.

G.657 optical fibers are intended to be compatible with the G.652 optical fibers but have differing bend sensitivity performance. It is designed to allow fibers to bend, without affecting performance. This is achieved through an optical trench that reflects stray light back into the core, rather than it being lost in the cladding, enabling greater bending of the fiber. As we all know, in cable TV and FTTH industries, it is hard to control bend radius in the field. G.657 is the latest standard for FTTH applications, and, along with G.652 is the most commonly used in last drop fiber networks. With the amount of energy now required to power the world’s data centers, one of the greatest challenges in today’s data centers is minimizing costs associated with power consumption and cooling, which is also the requirement of building the green data center. Higher power consumption means increased energy costs and greater need for heat dissipation. This requires more cooling, which adds even more cost. Under these circumstances, high-speed optical fiber offers a big advantage over copper to reduce the network operational and cooling energy.

With the amount of energy now required to power the world’s data centers, one of the greatest challenges in today’s data centers is minimizing costs associated with power consumption and cooling, which is also the requirement of building the green data center. Higher power consumption means increased energy costs and greater need for heat dissipation. This requires more cooling, which adds even more cost. Under these circumstances, high-speed optical fiber offers a big advantage over copper to reduce the network operational and cooling energy.