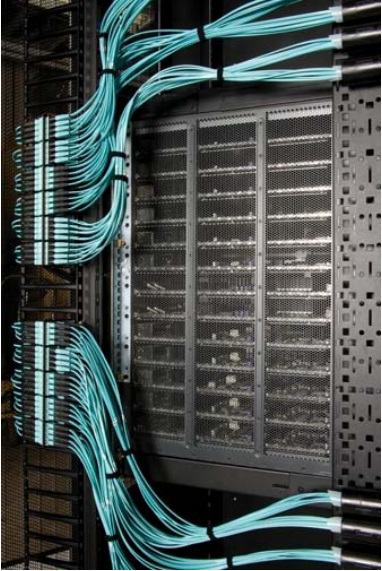

Data centers today consist of rows of server racks and network cabinets to support an abundance of data cables, power cords and network devices. Deliver proficient cable management within a confined and tightly-spaced server rack is quite difficult. However, cable management is no longer a nightmare if you follow the right guide and work with some test-and-tried tools. Here we’d like to offer useful advice for server rack cable management, and recommend some efficient and reliable management tools.

Server Rack Cable Management Benefits

Server rack cable management, if not being handled properly, could bring you a succession of problems – it would result in cable damage and failure, which directly lead to data transmission errors, performance issues and system downtime. On the contrary, successful cable management in server rack can benefit you in every aspects, including:

Improved system performance: server rack cable management demands to separate power and data cables within the racks, which greatly decrease the chance for crosstalk and interference.

Enhanced availability: Effective server rack cable management allows easier access to cables and IT devices, yet to reduce human error.

Improved maintenance and serviceability: Effective rack cable management also ensures easier and safer access to individual components.

Increased cooling efficiency: let hot exhaust air out from the back, server rack cable management keeps cables organized and out of critical airflow paths.

Improved scalability: cable management in server rack simplifies moves, adds, and changes, making it easier to integrate additional racks and components for future growth.

Server Rack Cable Management Guide

Since we’ve made clear the benefits of server rack cable management, here is a step-to-step guide for you to further explain how to do it correctly:

- Plan appropriately. It greatly contributes to smooth server rack management process. Consulting a professional cabling contractor can always be beneficial.

- Determine the routes for power and data cables. Determine if they enter from the top or bottom of the server rack. Then plan the routes to separate power and data cables, and copper data cables and fiber.

- Identify cables. Use colored cables as well as cable labers to ensure easier cable identification.

- Route and retain cables. Cables must be protected at points where they might encounter sharp edges or heated areas. Cable ties and cable managers can be used to this end.

- Secure cables. Cables and connectors should be secured to prevent excessive movement and to provide strain relief of critical points.

- Avoid thermal issues. Ensure the airflow path is rather important, since restrained airflow can cause temperatures rise that would shorten devices’ expected lifespan.

- Document and maintain organization. Documenting the complete infrastructure including diagrams, cable types, patching information, and cable counts is important.

Efficient Tools for Server Rack Cable Management

Here are top five management tools that can facilitate cable management in server racks:

Horizontal cable managers are excellent for any kind of cable – fiber, coax, patch cables, copper wiring and more to ensure that your cables are well-organized and protected. Horizontal cable managers come with rack-mountable 1U or 2U design, and some of them are built with finger duct and D-rings for easier finger access in server rack.

Vertical cable manager work very well to organize and hold cables to ensure proper air flow, avoiding overheating in complex server rack environment. They’re also great for installations where you need to save space or need to make more room in the future to expand your network.

If you need to organize cabling within server racks, cable hangers can come in handy. Cable trays are excellent for running wires from one place to another and can be mounted on the floor or overhead in the ceiling.

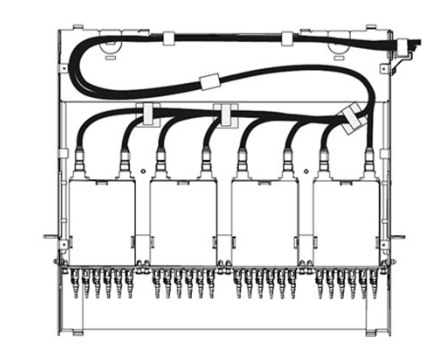

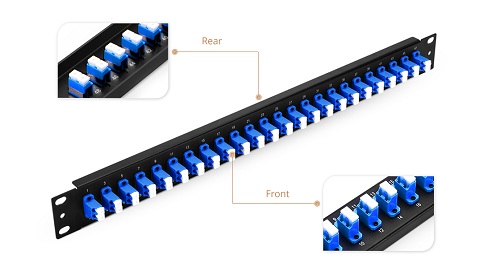

For data and telecommunications networks a copper patch panel is essential. A patch panel is a board with a number of different ports to connect network wiring. Ethernet patch panels are available in a variety of different configurations depending on your cable types and needs: there are Cat5e patch panel, Cat6 patch panel and Cat6a patch panel, each with different port counts such as 24-port patch panel, 48-port patch panel, etc. Copper patch panel is also great for consolidating cables so that your server rack looks neat and organized.

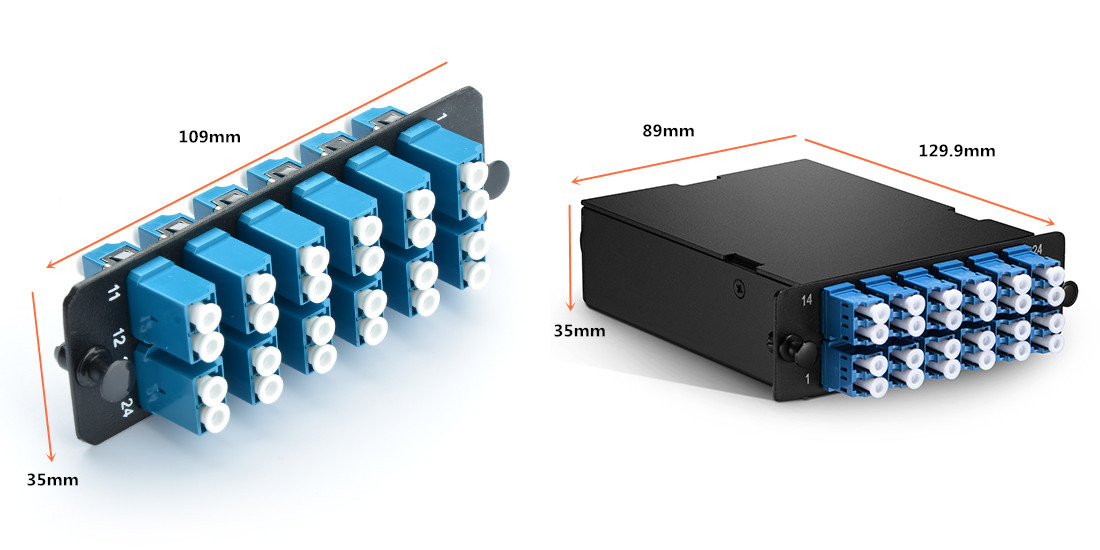

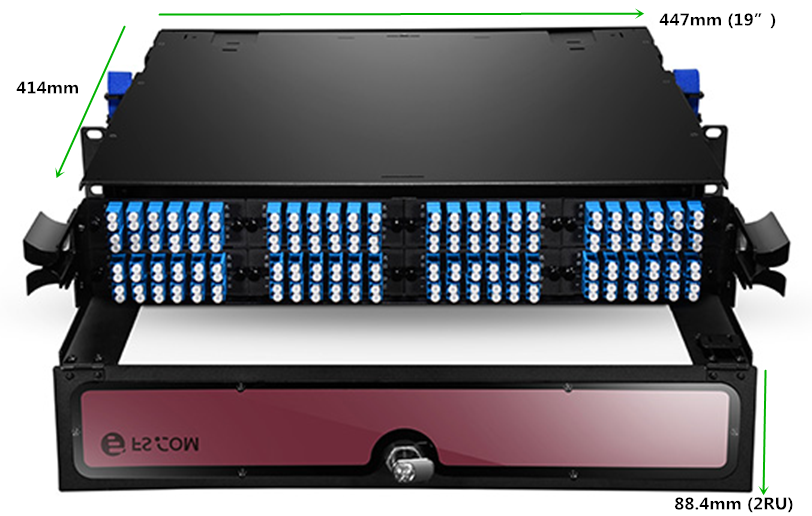

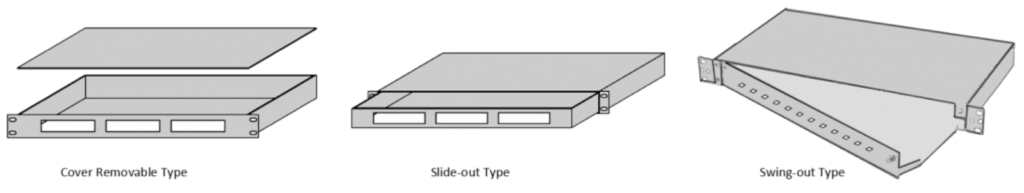

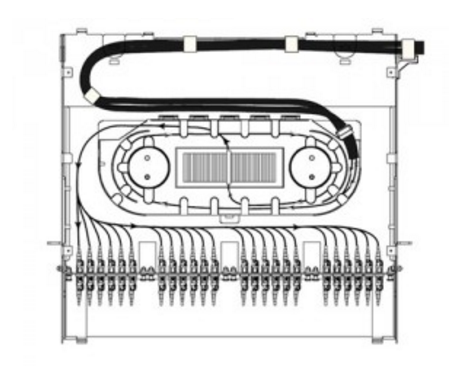

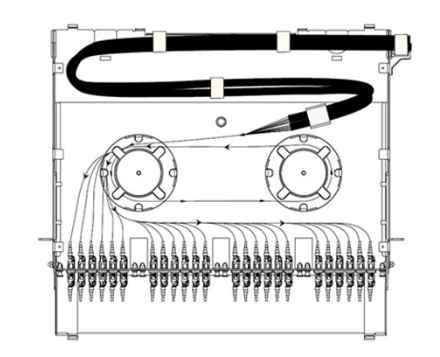

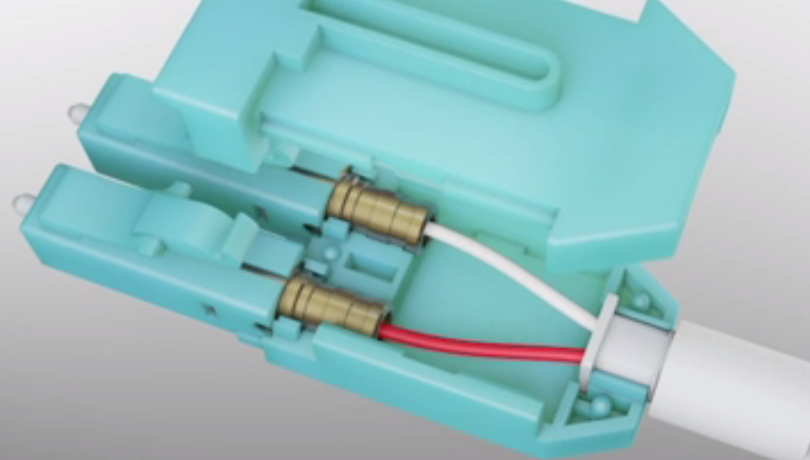

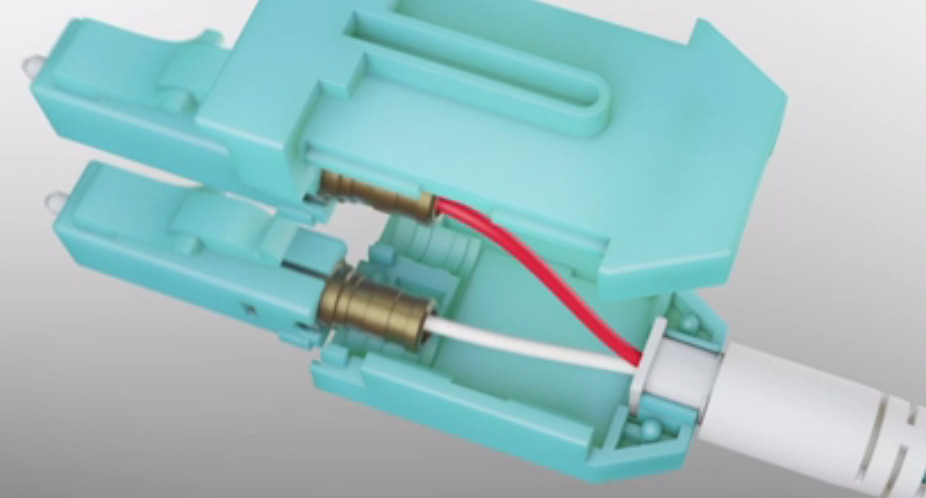

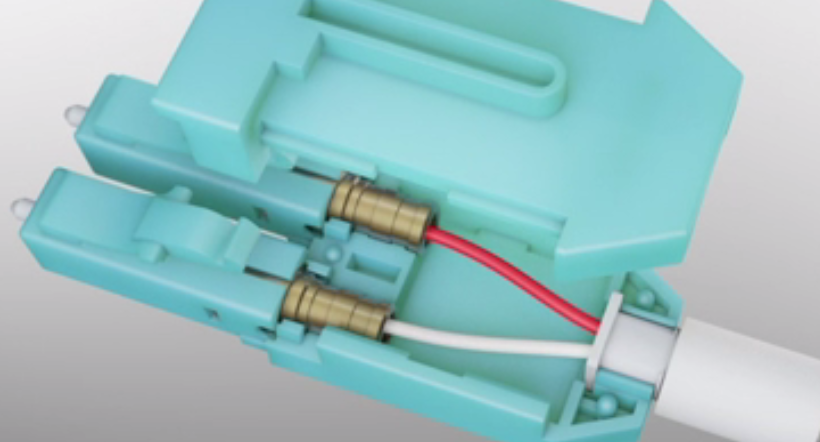

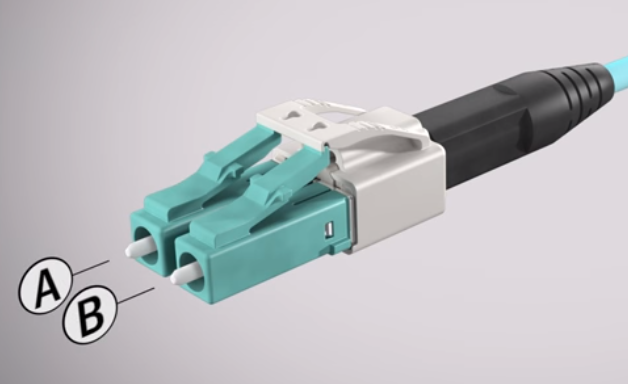

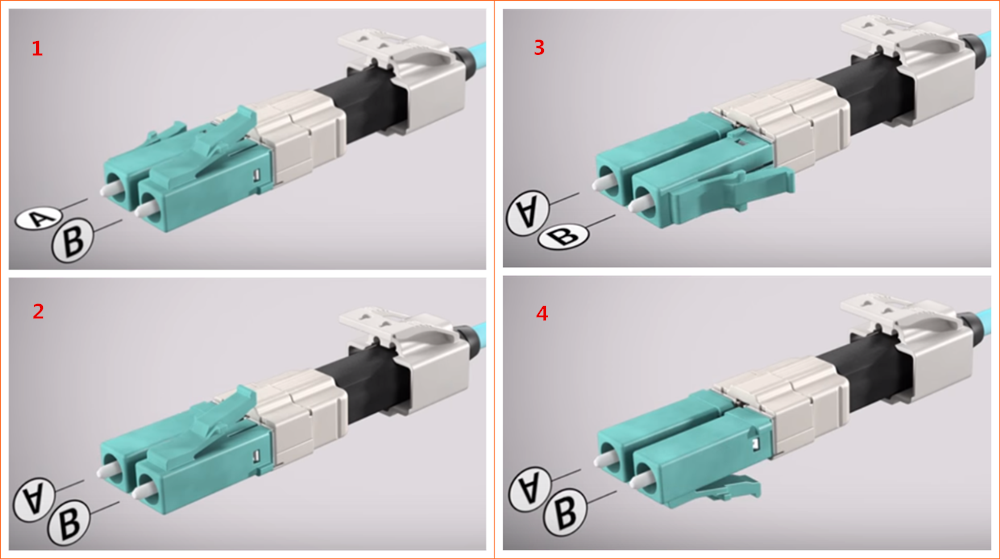

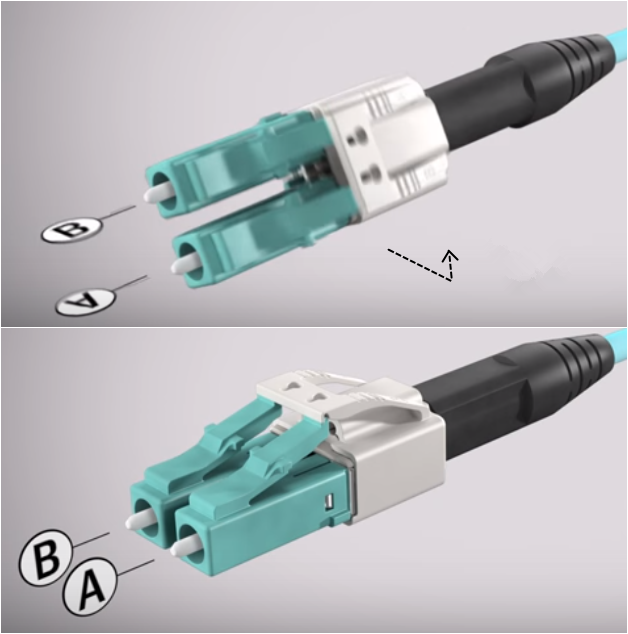

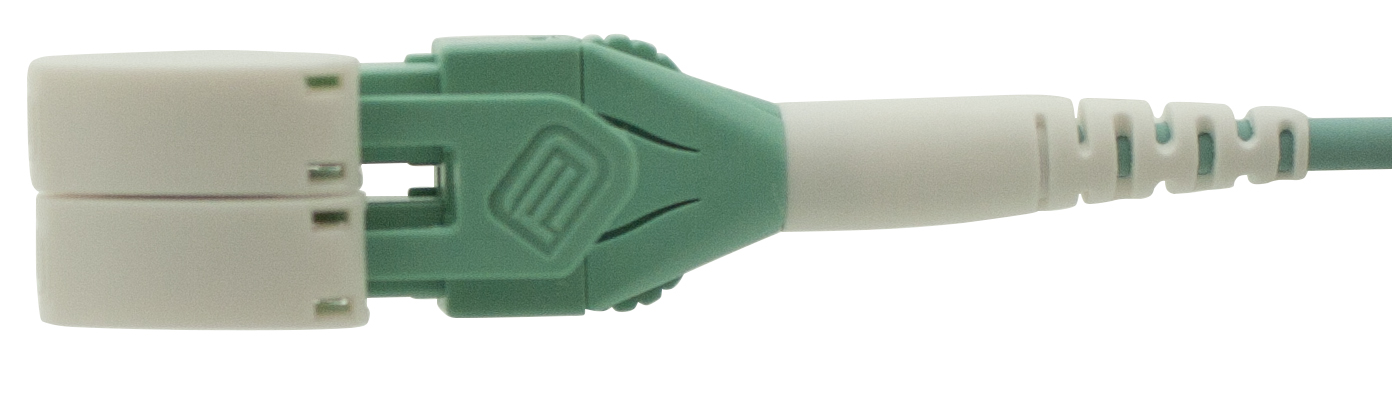

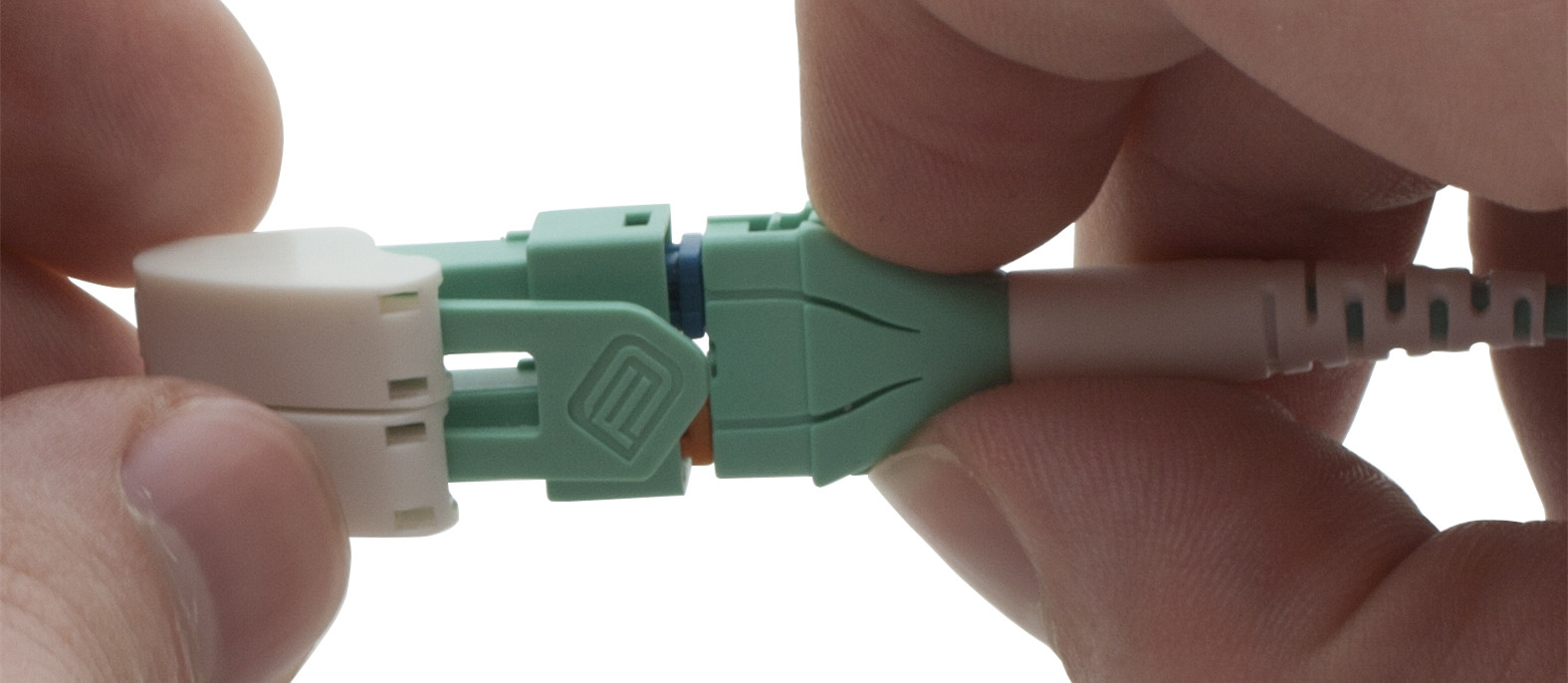

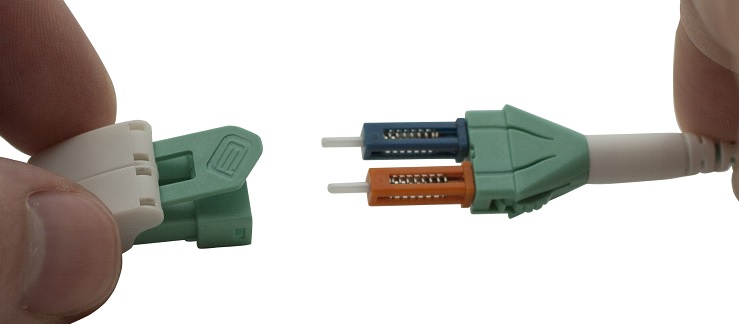

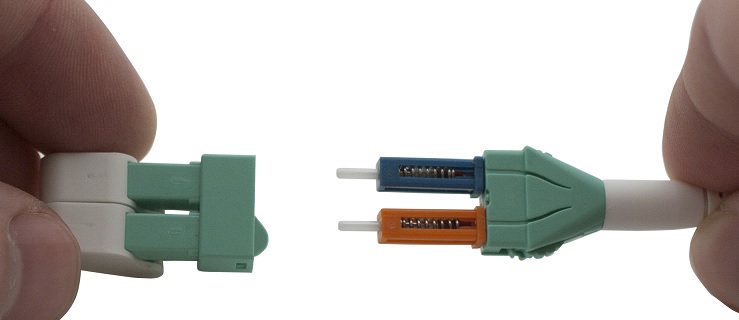

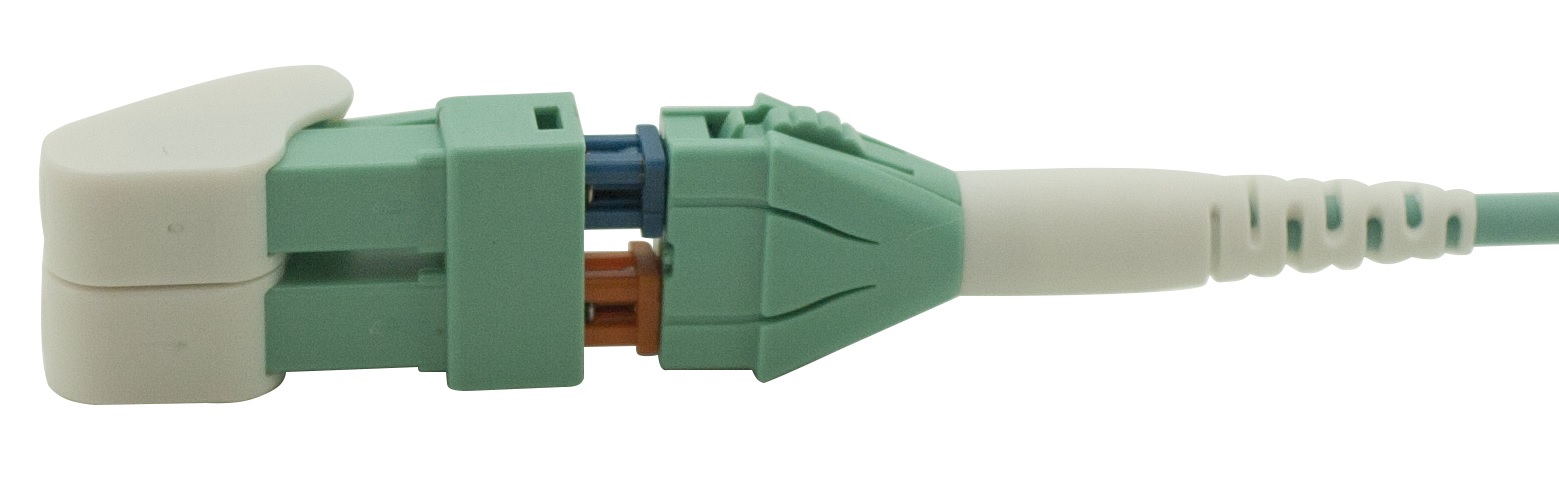

Similar to data patch panels, fiber patch panels are designed specifically for fiber optic cables. Also known as termination units they can accommodate connectors, patch cables and more. Network technicians can easily connect cable fibers through cross connection, test the cable patch panel, and connect it to other network equipment. Grouping by the connector type, there are single mode and multimode LC/SC/MTP fiber patch panels with various port counts. You can also choose blank patch panel to mix and match your fiber and copper cabling.

Conclusion

Effective server rack management helps to improve physical appearance, cable traceability, airflow, cooling efficiency and troubleshooting time while eliminates the chance for human error. Hope our guide on server rack cable management would help solve your problem. FS.COM provide tailored cable management solutions for our customers, as well as management tools like cable manager, patch panel, cable organizer and cable tie. If you need any help, please contact us at sales@fs.com.