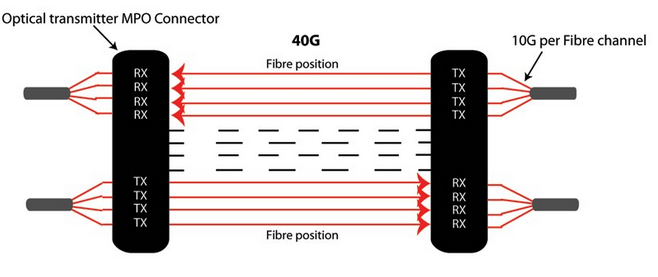

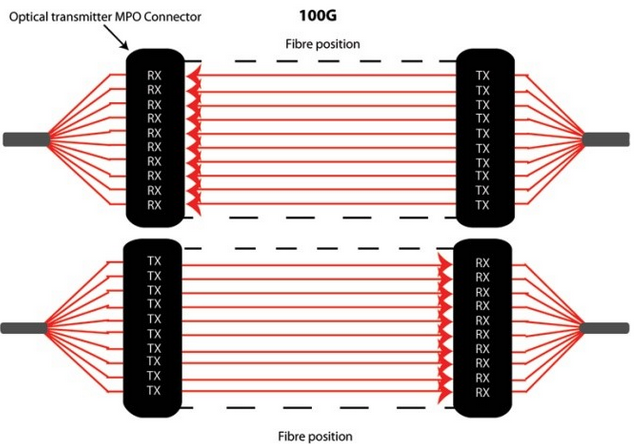

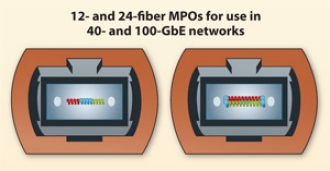

As we all know, the standard specifies MPO as a connector to the 40GBASE-SR4/CSR4 QSFP+ transceiver. To connect a QSFP+ to QSFP+, we usually use a MTP 12-fiber trunk cable. In the 40GBASE-SR transmission, there are eight fibers associated with the channel—four fibers for the TX signal and four fibers for the RX signal. Therefore only 8 of the 12 fibers are used, where the remaining four are not used, and can optionally be not present in the cable. So we can also choose a MTP 8-fiber trunk cable for connectivity. This article explains 40G QSFP+ SR4/CSR4 transceiver to 40G QSFP+ SR4/CSR4 transceiver cabling selections.

How to Choose Right MTP Trunk Cables?

In addition to using a MTP 8-fiber trunk cable or MTP 12-fiber trunk cable, there are a number of other factors also needed to be considered when to choose a right MTP trunk cable for 40G QSFP+ SR4/CSR4 transceiver connectivity.

- Use single-mode or multimode MTP trunk cable?

In the market, both single-mode and multiode MTP trunk cable are available. Which one should I use? According to 40GBASE-SR4 standards, 40G QSFP+ SR4 transceiver supports link lengths of 100 meters and 150 meters, respectively, on laser-optimized OM3 and OM4 multimode fibers. Therefore, to connect a 40G QSFP+ SR4 to 40G QSFP+ SR4, we should choose OM3 or OM4 multimode MTP trunk cables.

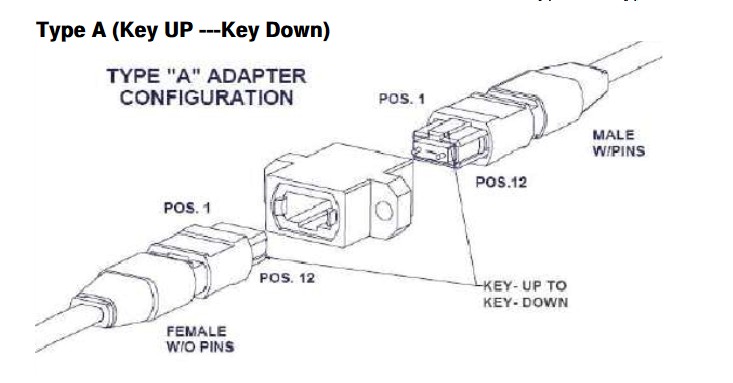

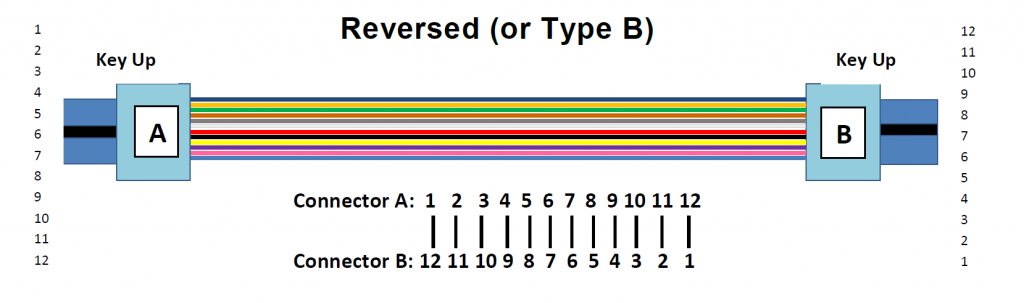

- MTP trunk cable polarity selection: A, B or C?

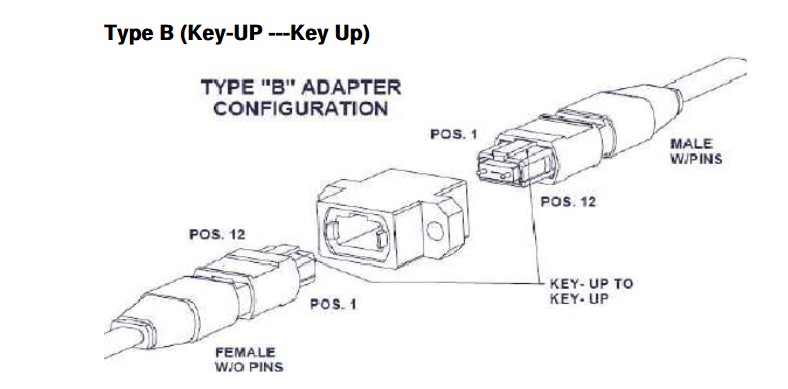

In terms of MTP trunk cable, there are three kinds of polarity options (A, B and C). Which one to choose? In fact, according to the IEEE 40GBASE-SR4 specifications, we must select a type B MTP 8-fiber or MTP 12-fiber trunk cable. The type B trunk cable has opposing connectors with both keys oriented facing up, however the fiber positions are reversed at each end i.e. the fiber at position 1 at one end is connected to position 12 in the connector at the opposing end.

- Choose male or female MTP trunk cable?

In terms of a MPO connector, it is divided into male and female types. They ensure that the adapter holds the connector with the correct ends aligned with each other. A MPO trunk cable usually has two MPO connector on each side. Therefore, MTP trunk cables are available in male–male and female–female two versions. According to IEEE standards, MPO optics in a 40G QSFP+ SR4 transceiver are always male connectors, and therefore will always accept female MPO connectors. So if we want to connect a 40G QSFP+ SR4 transceiver to a 40G QSFP+ SR4 transceiver successfully, we must choose a female–female MTP trunk cable.

40G QSFP+ SR4/CSR4 to 40G QSFP+ SR4/CSR4 Cabling Selections

In order to satisfy different cabling requirement, we may choose different cabling methods. And different cabling methods call for many different cabling infrastructure. Following are four type common cabling methods to connect a 40GBASE-SR4/CSR4 QSFP+ to 40GBASE-SR4/CSR4 QSFP+.

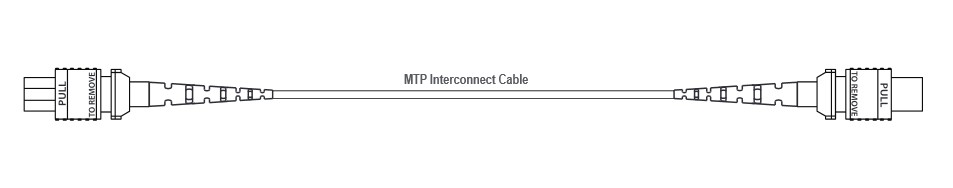

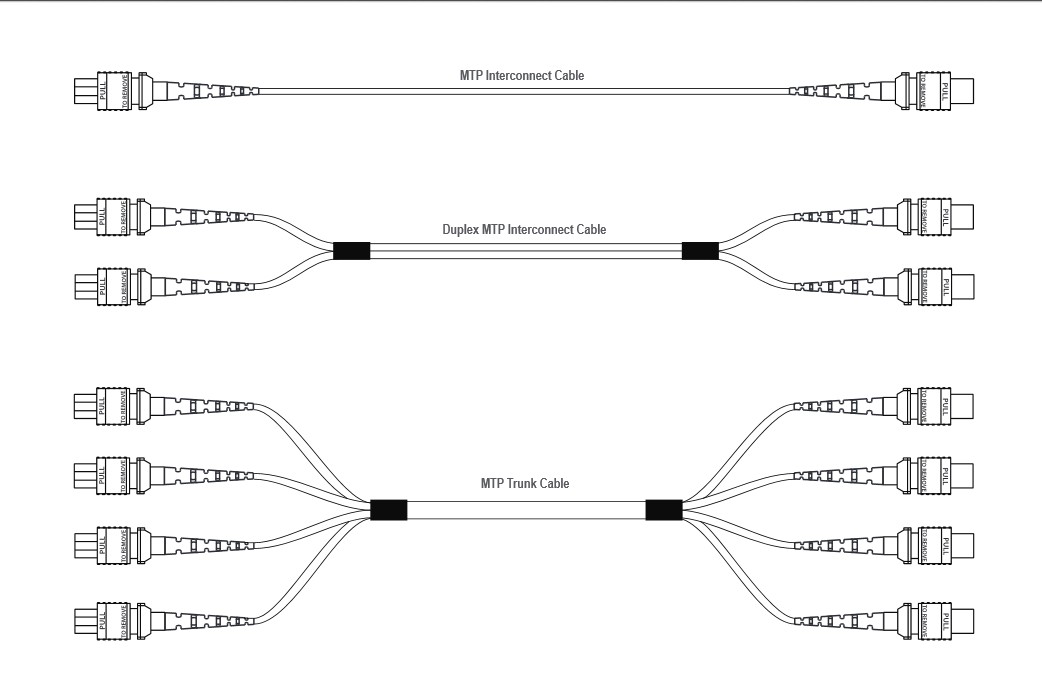

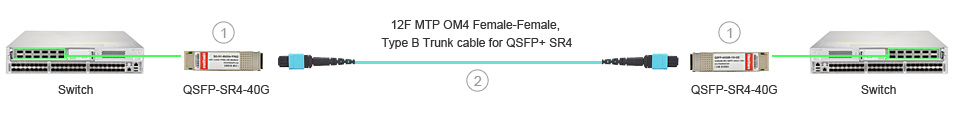

- Direct connection for 40 Gigabit Ethernet parallel optic transceiver

When directly connecting one QSFP+ MPO/MTP interface transceiver to another, a Type-B female MPO/MTP to female MPO/MTP cable is required. This type of direct connectivity is only suggested for short distances within a given row of racks/cabinets. Following picture shows two QSFP+ transceivers being connected with a MTP female cable.

| Item Number | FS Correlative Product Description | FS Part Number |

| 1 | 40GBASE-SR4 QSFP+, 850nm, 150m, MMF, MPO interface | QSFP-SR4-40G |

| 2 | 12 Fibers OM4, 12 Strands MTP Trunk Cable, Female to Female, Type B Polarity ( MTP/ MPO, OM4/ OM3 optional. Various lengths available) | FS12OM4-2MTP-FF-B |

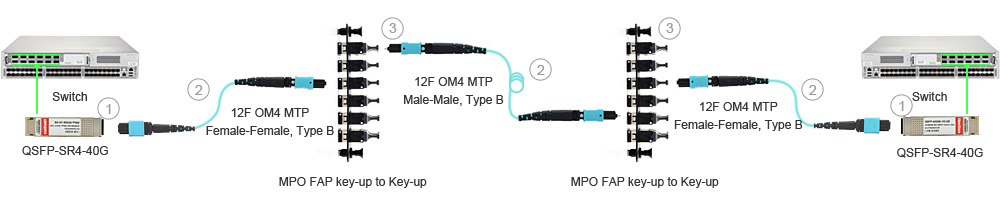

- 40GbE direct interconnect with MTP trunk cable and patch panel

For distances less than 400 meters, the use of FS MPO/MTP multi-mode fiber cabling is generally the preferred cabling method. The next solution is similar to the previous, but instead of using a 12-fiber jumper directly, the MPO/MTP adapter panel is interconnected. Following picture shows the distribution switch and FS optics and cabling options with corresponding item details for a QSFP+ to QSFP+ multi-mode interconnection.

| Item Number | FS Correlative Product Description | FS Part Number |

| 1 | 40GBASE-SR4 QSFP+, 850nm, 150m, MMF, MPO interface | QSFP-SR4-40G |

| 2 | 12 Fibers OM4, 12 Strands MTP Trunk Cable, Female to Female, Type B Polarity ( MTP/ MPO, OM4/ OM3 optional. Various lengths available) | FS12OM4-2MTP-FF-B |

| 3 | 12 Ports MTP/MPO Fiber Adapter Panel, key-up to key-up | FAP-HV-12MTPUUD |

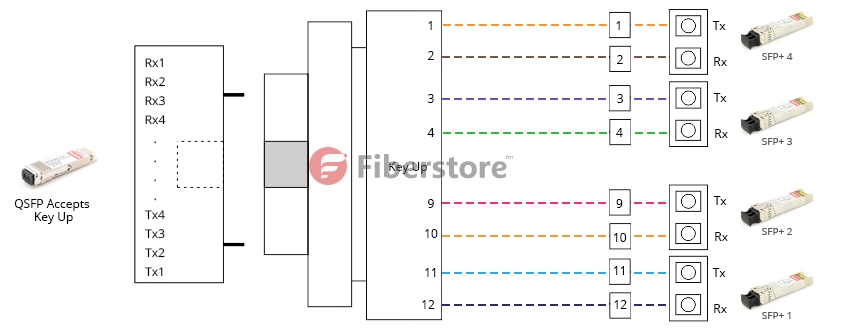

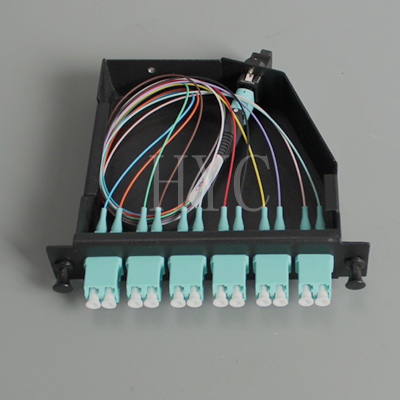

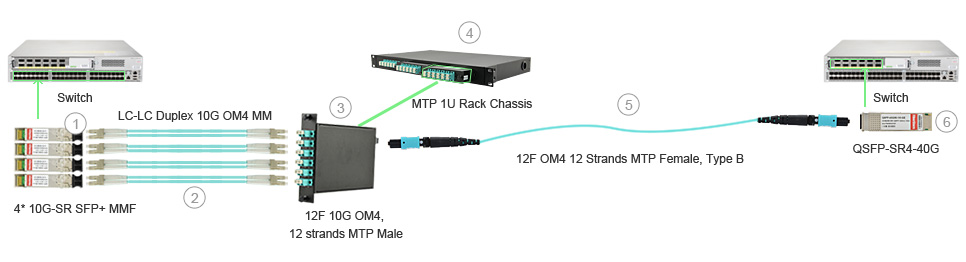

- 10Gig migrate to 40GbE by interconnecting MTP LGX cassette and MTP trunk cable

Following picture shows one link with a breakout of the QSFP+ with the use of an MPO/MTP LGX cassette to four 10G SFP+ links. A Type-B female MPO/MTP to Female MPO/MTP assembly is used between the MPO/MTP LGX cassette and 40GbE transceiver. The connections to the SFP+ transceivers is accomplished with OM3/OM4 Uniboot LC duplex fiber patch cables.

| Item Number | FS Correlative Product Description | FS Part Number |

| 1 | 10GBASE-SR SFP+, 850nm 300m, MMF, LC duplex | SFP-10GSR-85 |

| 2 | LC-LC Duplex 10G OM4, MMF Patch Cable | OM4-LC-LC-DX-FS |

| 3 | 12 Fibers OM4, LGX – MTP Cassette, MTP(male) to LC | FS12OM4-LGX-2MTP-LC |

| 4 | MTP/MPO LGX Cassettes 1U/4U 19” Rack Mount | FS-1RU-MX |

| 5 | 12 Fibers OM4, 12 Strands MTP Trunk Cable, Female to Female, Type B Polarity ( MTP/ MPO, OM4/ OM3 optional. Various lengths available) | FS12OM4-2MTP-FF-B |

| 6 | 10GBASE-SR SFP+, 850nm 300m, MMF, LC duplex | SFP-10GSR-85 |

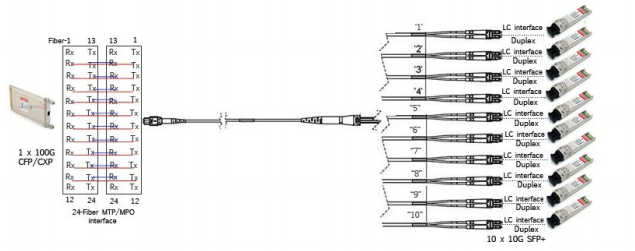

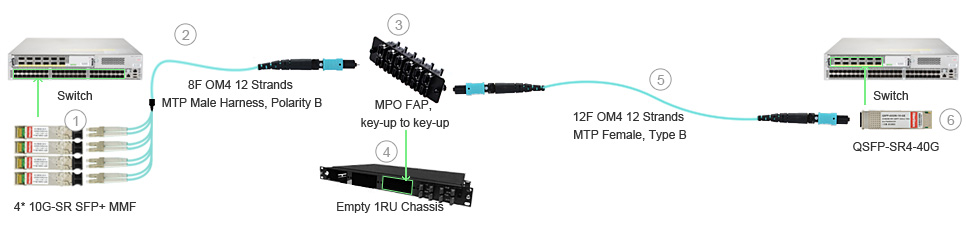

- 10Gig migrate to 40GbE by interconnecting MTP harness cable and MTP trunk cable

Sometimes, create a simple, cost-effective migration path by installing a structured cabling system that can support your future 40GbE networking needs. Following picture uses the 8-fiber harness as shown in the diagram to connect to 10G SFP+s. This approach allows for an easy upgrade path moving from 10Gig to 40GbE connectivity.

| Item Number | FS Correlative Product Description | FS Part Number |

| 1 | 10GBASE-SR SFP+, 850nm 300m, MMF, LC duplex | SFP-10GSR-85 |

| 2 | 8 Fibers OM4, 12 Strands MTP Harness Cable, MTP to LC, Type B Polarity ( MTP/ MPO, OM4/ OM3 optional. Various lengths available) | OM4-LC-LC-DX-FS |

| 3 | 12 Ports MTP/MPO Fiber Adapter Panel, key-up to key-up | FAP-HV-12MTPUUD |

| 4 | Empty 1RU/4RU Rack Mount Fiber Patch Panel | FMT1-E-FS |

| 5 | 12 Fibers OM4, 12 Strands MTP Trunk Cable, Female to Female, Type B Polarity ( MTP/ MPO, OM4/ OM3 optional. Various lengths available) | FS12OM4-2MTP-FF-B |

| 6 | 40GBASE-SR4 QSFP+, 850nm, 150m, MMF, MPO interface | QSFP-SR4-40G |

Fiberstore provides wide brand compatible 40G QSFP+ SR4 transceivers and all kinds of MTP cables. Each fiber optic transceiver has been tested to ensure its compatibility and interoperability. Please rest assured to buy. For more information or quotation, please contact us via sales@fs.com.

Related Article: 40G Transceiver Module: QSFP+ Module And CFP Module