Introduction

Data centers are the central location for data interchange and are found in enterprises, government offices, schools, universities, hospitals, and other networked server farms. The ease of turning nearly any location into an information interchange hub has been enabled by the development of array-based fiber optic cabling systems. Ribbon fiber cables, array-based fiber connectors, and packaged breakout assemblies like fiber optic cassette provides modular small form factor connectivity and enable fast, reliable interconnection of fiber optic links in high-density data center environments.

Once the decision has been made to deploy array-based fiber connectivity, care must be taken to ensure the integrity of connections between the transmitting optical light source and the receiving photo detector. The matching of the transmit signal (Tx) to the receive equipment (Rx) at both ends of the fiber optic link is referred to as polarity. The objective of polarity is simple: provide transmit-to-receive connections across the entire fiber optic system in a consistent, standards-based manner.

Preterminated fiber MTP MPO optical cassettes and loose-tube or ribbon fiber backbone cables are the heart of a modular fiber system. The cassettes and cables typically support groups of full-duplex fiber connections. The challenge for the network system designer becomes one of assuring the proper polarity of these array connections from end to end.

This white paper describes the methods defined in the ratified TIA/EIA (Telecommunications Industry Association/Electronic Industries Association) standard to assure correct polarity using MPO multi-fiber array connectors, cables and cassettes.

Standards and methods:

The TR-42.8 Technical Engineering Subcommittee has developed a standard that addresses the polarity issues associated with multi-fiber array connections. (This document, TIA-568-B.1-7, is available through the Internet for purchase as a reference document.)

Currently, a new release of the TIA-568 Commercial Building Cabling Standard is under development as the TIA-568-C series of standards. The fiber-systems section of this series will be TIA-568-C.1, and will include information on array system polarity along with a description of MPO array cables, duplex patch cords, and array transitions.

Modular fiber optic cassettes:

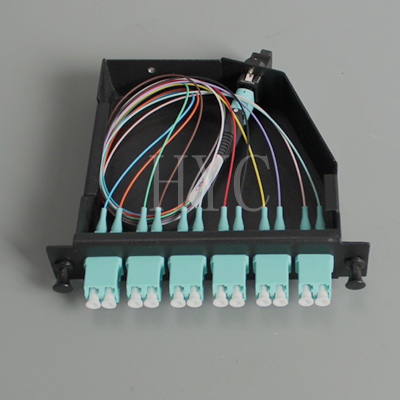

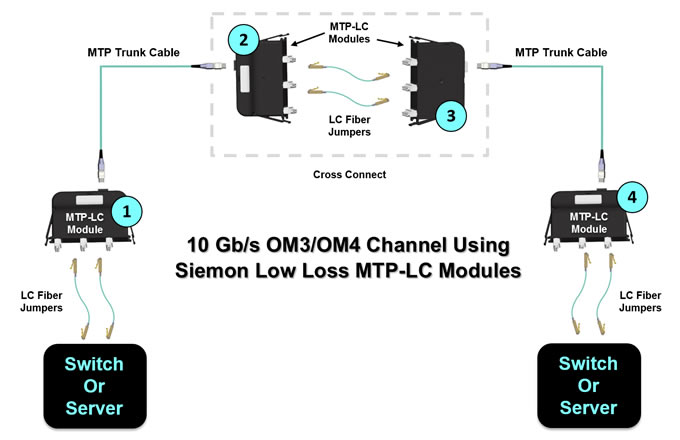

Modular fiber optic cassettes-enclosed units containing 12- or 24-fiber factory-terminated fanouts-serve to transition small-diameter ribbon cables terminated with an MPO connector to the more-common LC or SC interfaces used on the transceiver terminal equipment. The fanouts typically incorporate SC, LC, ST-style or MT-RJ connectors plugged into adapters on the cassette’s front, and an MPO connector plugged into an MPO adapter on the cassette’s rear side.

One or more MPO fanout assemblies may be installed inside the fiber optic cassette to connect up to two, 12-fiber ribbon cables, for a total of 24 fibers. Alignment pins that are preinstalled in the MPO connector within the cassette precisely align the mating fibers in the MPO conn

ectors at either end of the array cables that plug into the cassettes.

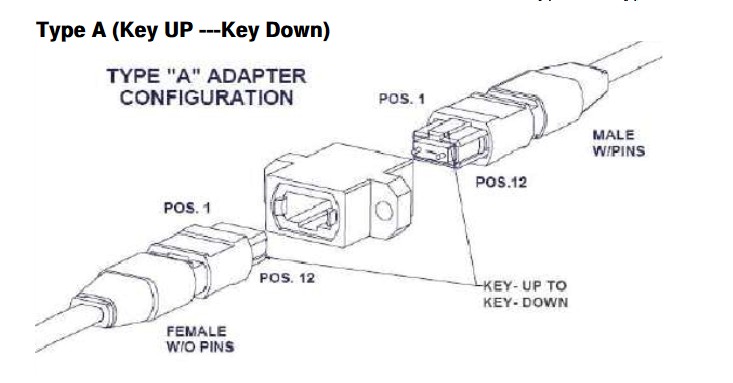

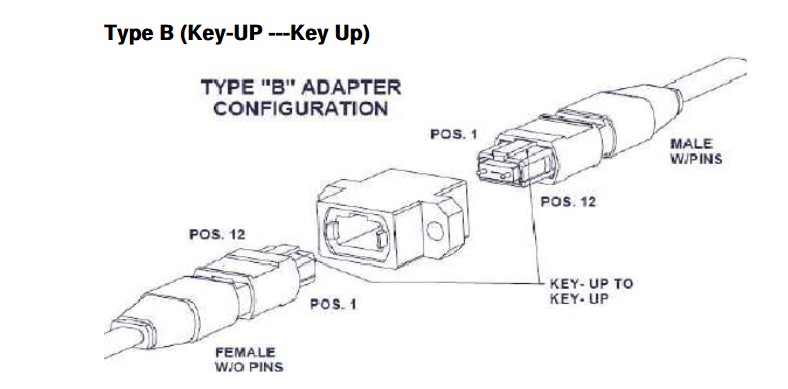

The transition that takes place inside a fiber optic cassette, the connector keying for the cassette and the corresponding MPO array cables are all thoroughly defined for all three connectivity methods listed in the TIA standard. A common transition, factory-installed inside a cassette, is used for all three methods. The adapter mounted at the rear of a cassette defines it as either a Method A or Method B type. The only difference between the two cassette types is the orientation of the internal MPO connector with respect to the mating MPO array cable connector.

Method A cassettes make a “key up”-to-“key down” connection between the internal MPO connector and the MPO array cable connector. Method B cassettes make a “key up”-to-“key up” connection. It is important to note that a Method B cassette will not allow single mode angle-polish mated-pair connection because the angles of the mating connectors are not complementary. This prevents a Method B cassette or adapter from being used in single mode applications that require low return losses-a significant limitation.

MPO array cables:

Modular fiber optic cassettes are connected to one another with MPO to MPO ribbon backbone cables. The connectors on these cables do not contain alignment pins, but they do have mating alignment holes. Alignment pins are factory-installed in the MPO fanout connectors installed inside the fiber optic cassette.

The TIA standard defines three different 12-fiber MPO cable: Types A, B, and C. Each is used for its respective connectivity method (Methods A, B, and C).

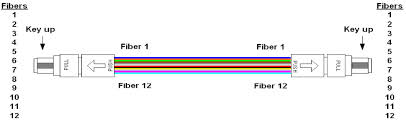

For the Type, A array cable, the opposing connections at each end of the cable have the same fiber positions, except that one end has the key oriented facing up while the other end has the key oriented facing down.

The Type B array cable has opposing connectors with both keys oriented facing up, but the fiber positions are reversed at each end; the fiber at position 1 at one end is connected to position 12 in the connector at the opposing end.

In the Type C array cable, the key is facing up at one end and facing down at the other end. It looks like a Type-A array cable, but the Type-C cable is designed such that adjacent pairs of fibers are crossed from one end to the other. In this case, the fiber at position 1 on one end of the cable is shifted to position 2 at the other end of the cable. The fiber at position 2 on one end is shifted to position 1 at the opposite end, and so on.

Connectivity methods:

The fiber patch cord, cassette (transition) and array cable previously described are used in specific combinations to form end-to-end full-duplex fiber links. Each component of the total fiber cabling system is unique, underscoring the importance of assuring that the correct component is selected and used in the proper sequence.

Importantly, regardless of which method defined in the TIA standard you use, there must be a pair-wise flipping (A-to-B polarity swap) that takes place at some point in the link. If the pair-wise flipping does not occur in the cassette (transition), then the pair-wise flipping must occur in the duplex patch cord, or in the MPO-to-MPO array cables and/or adapters.

Conclusions:

Modular fiber optic cassette-based cabling technology offers many advantages facilitating high-performance, rapid, and error-free installation, as well as reliable, robust operation. The best way to maintain correct optical polarity in these systems is to select a standards-based approach and to adhere to it throughout an installation. The three connectivity methods defined in the TIA/EIA-56-B.1-7 standard present the guidelines for maintaining polarity using array connections.

It is in the best interest of the installer and end-user to select modular fiber optic cassette-based solutions that adhere to TIA standards. Proprietary non-standards-based solutions will not assure interoperability. In addition, those solutions may not be compatible with commercially based components designed to meet the TIA standards. Selecting modular fiber systems that comply with TIA standards can help to prevent costly troubleshooting and rework of the installed fiber cable plant. Additionally, fiber-network installers can be assured of a readily available product supply from multiple stocking supply sources with acceptable delivery lead times.