Multi-fiber technology is has exploded as a result of today’s high fiber counts and limited space requirements which Data Centers demand. Fiberstore is today’s leader in the manufacturing of MTP cables and MTP Cassette. Fiberstore engineers unique MTP solutions utilizing 12, 24, 48 and even 72 fiber MTP ferrules. Now the following is the feature and benefits of MTP cassettes and cable assemblies.

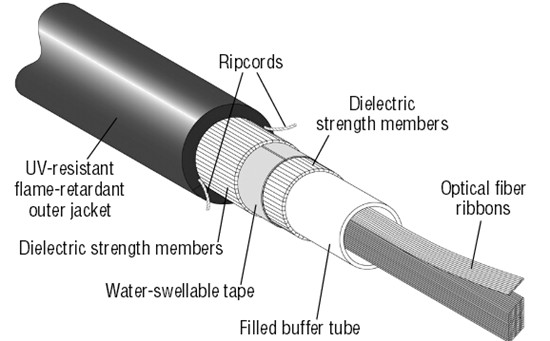

MTP cassettes and cable assemblies take their name from the MTP MPO connector, designed and introduced as a performance version of MPO connectors. MTP fiber systems are truly an innovative group of products. Each MTP connector contains 12 fibers or 6 duplex channels in a connector that is smaller than most duplex connections in use today. A 72 fiber trunk cable can be terminated with six MTP connectors and MTP connectors are manufactured specifically for multifiber loose tube or ribbon cable.

MTP connectors allow high-density connections between network equipment in telecommunication rooms. They use a simple push-pull latching mechanism for easy and intuitive insertion and removal. The ends of MTP brand connectors may be polished flat or at an 8° angle. An MTP brand connector is about the same size as a SC connector however it can accommodate 12 fibers, which provides up to 12 times the density, thereby requiring much less card and rack space.

A standard MTP cassette has one port in the back with a MTP coupler awaiting connection of an MTP cable assembly that has 12 fibers in the connector. The MTP cable plugs into the back and through the adaptor. The cable connects to another MTP assembly inside the cassette that “fans out” to 12 SC or LC connections. One MTP cable can connect up 12 different ports. From there you simply plug in your patch cables.

APPLICATIONS

* Suitable for high-density switch to patching and distribution in Data Center Applications (based on 72 fiber MTP ferrule)

* Used in optical transmitters and receivers, MTP brand connectors offer up to 36 times the density of standard connectors, providing significant space and cost savings.

* Compact design addresses high fiber count applications, with small and lightweight cables ideal for use with installation space limitations.

* MTP brand cable trunks offer flexibility in changing the connector style in the patch panels. New cassettes can be installed with the new connector style on the cross-connect side of the patch panel without having to change the connector on the cable trunk.

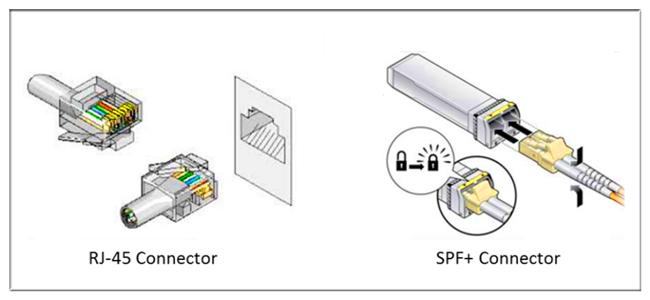

* The MTP brand connector is the standard for delivery of 40G (in its 12 fiber version) and 100G (in either a duplexed 12 fiber cable or 24 fiber ferruled cable) using QSFP transceivers.

Multi-fiber technology will eventually replace the standards for fiber optics as we know it. Even now people are tearing out their existing infrastructure and placing MTP cassettes in their patch panels to route data for thousands of network electronics. MTP cassettes, cables, connectors and adapters are essential to backbone infrastructure. The high fiber count in one connector creates endless possibilities. Imagine a 1U rack mount patch panel that can supply data to run an entire 288-port switch. With today’s increasing demand for higher through-put, ST, SC, MTRJ, LC, FC, etc, will all be a thing of the past.

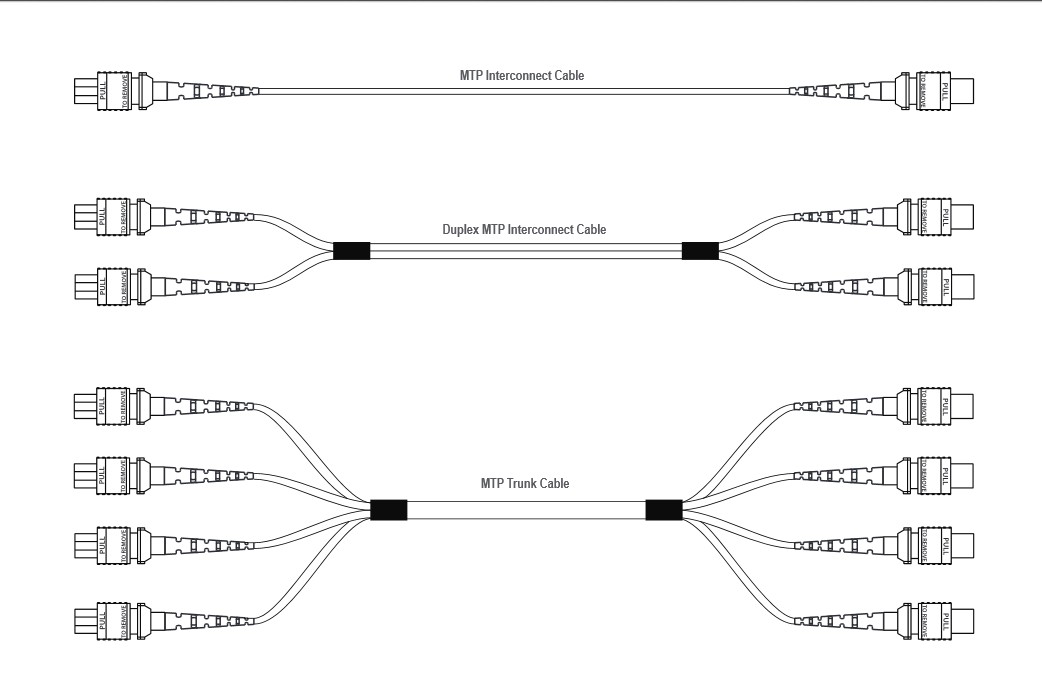

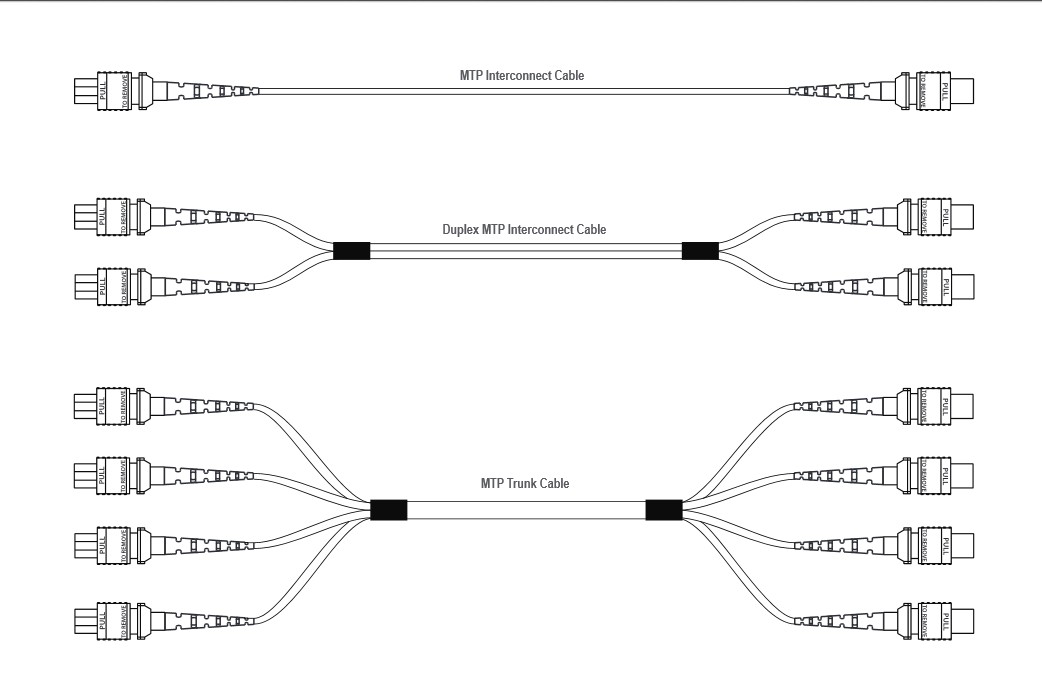

MTP Fiber Optic Cables are multi-fiber patch cords suitable for high-density back plane and PCB solutions. MTP patch cords offer up to 36 times the density (based on a 72 fiber ferrule) of traditional patch cords, providing significant space and cost savings. There are several configurations for MTP brand cable assemblies. The most popular is a MTP connector to MTP connector patch or trunk cable that connects an MTP brand cassette to another MTP brand cassette. If an MTP adapter panel is installed in a patch panel, then an MTP cable to MTP brand can be used as well.

Another configuration is MTP connectors to LC or SC fiber connector. These can be used in different applications for both back end and front end adapter panels, for instance, plug one MTP connector into the back and plug an MTP cable to LC cable into the front and have the 12 LC connections go to other equipment. If there is an MTP cassette that needs to be lit up by using a 12-fiber LC adapter panel, plug each of the 12 LC connections in the LC adapter panel. The MTP side then plugs into the back of the cassette. Increase the transfer speed with 10 Gig 50 Micron multimode cable or increase the distance the signal can travel using singlemode. Cables may be constructed of ribbon fiber, small form factor loose tube assembly cable, or subgrouped trunking cable. The options are only limited by the application.

MTP/MPO Cassettes are specially designed to reduce installation time and cost for an optical network infrastructure in the premises environment. MTP/MPO Cassettes provide secure transition between MTP/MPO and SC, LC, ST, or FC connectors. They are used to interconnect MTP/MPO backbones with LC/SC/ST/FC patching. Fiberstore MTP cassettes come in a variety of connector styles and modes. From Multimode to Singlemode, from SC to LC, MTP brand solutions can be the solution to save space, time, and energy.

By plugging an MTP brand cable into the back, 12 or 24 (with quad LC) connections are being lit up . For the 24-fiber application, either one 24-fiber MTP brand cable or two 12-fiber MTP brand cables can be used. The cassette can be snapped into any standard fiber optic patch panel including both rack mount and wall mount. A RAC-1X holds three of these cassettes which could potentially contain 72 active LC connections using only three (or six) MTP brand cables. Clean up the clutter and increase your possibilities using MTP brand cassettes.

We supply MPO/MTP fiber optic cables, such as MPO MTP trunk cable, MPO/MTP breakout cable. These are available in Female to female or a male to male and male to female configurations. The male version has MTP pins. These can be made with 12 fiber MTP connectors, 24 Fiber MTP connectors, 48 Fiber MTP connector variations. We use USConec MTP fiber optic connectors for all of our MTP and MPO terminations so that the highest performance is accomplished. Many additional options and combinations are available. All multi fiber optic cables are customizable.

Small Package Makes Sense

Small Package Makes Sense 2.1bn by 2019.

2.1bn by 2019.

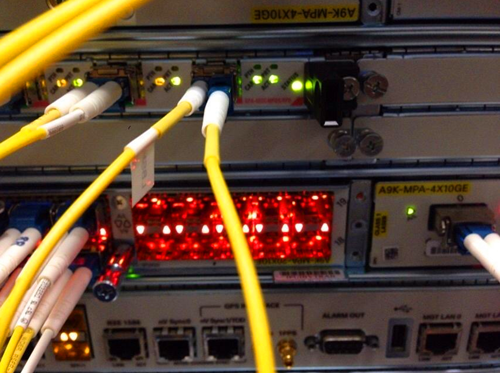

With the amount of energy now required to power the world’s data centers, one of the greatest challenges in today’s data centers is minimizing costs associated with power consumption and cooling, which is also the requirement of building the green data center. Higher power consumption means increased energy costs and greater need for heat dissipation. This requires more cooling, which adds even more cost. Under these circumstances, high-speed optical fiber offers a big advantage over copper to reduce the network operational and cooling energy.

With the amount of energy now required to power the world’s data centers, one of the greatest challenges in today’s data centers is minimizing costs associated with power consumption and cooling, which is also the requirement of building the green data center. Higher power consumption means increased energy costs and greater need for heat dissipation. This requires more cooling, which adds even more cost. Under these circumstances, high-speed optical fiber offers a big advantage over copper to reduce the network operational and cooling energy.