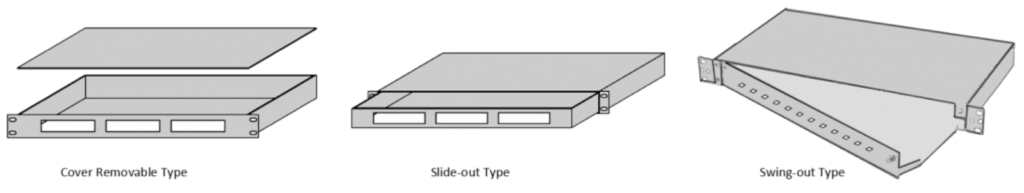

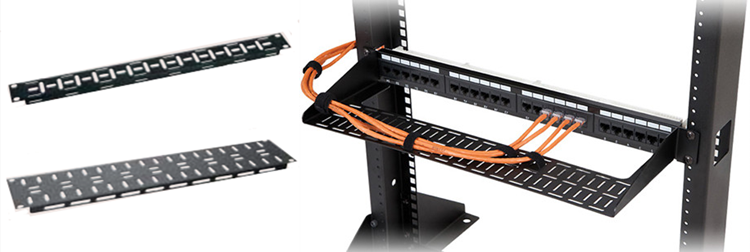

Nowadays, rack mount enclosure (or rack enclosure) is widely used in enterprise data centers, server rooms, schools, etc. to manage network cables. As one of the most popular options, 1U rack mount enclosure is a priority choice in many situations. While, normally, there are two styles (slide-out style and removable style) of enclosures in the same 1U rack space. Then, how to choose a proper one for your cabling? Next, let’s take the comparison on two types of FS 1U rack mount enclosures as an example.

FS FHD-1UFMT-N 1U Rack Mount Enclosure

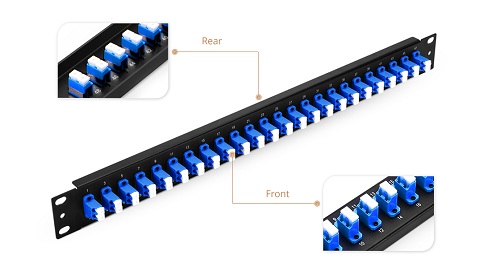

FHD-1UFMT-N is one of the FHD series products that self-developed by FS.COM. The FHD series products focus on easy-to-manage high density fiber cabling. It is a cost-effective and reliable solution for fiber cable management in data centers, server rooms, CATV (Cable TV), etc.

- Net Weight: 3.65KG

- Dimensions: 44mm(H) x 430mm(W) x 281.9mm(D)

- Material: Steel with black powder coating

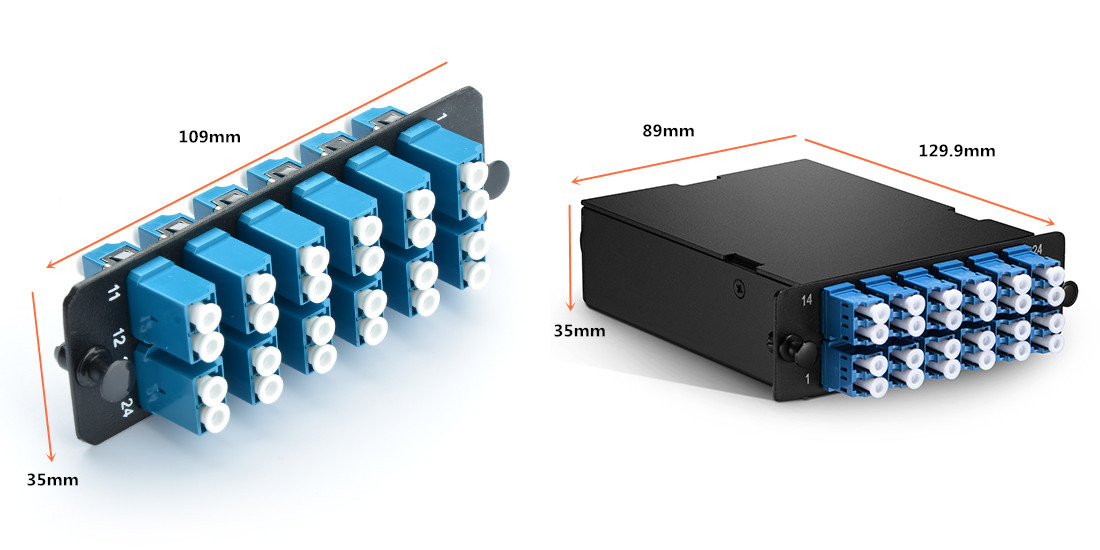

- Modular Design: 4 x FAPs or 4 x HD MTP/MPO cassettes can be loaded, up to 96 fibers

- Accessories: Mounting hardware and accessory kit with labels included

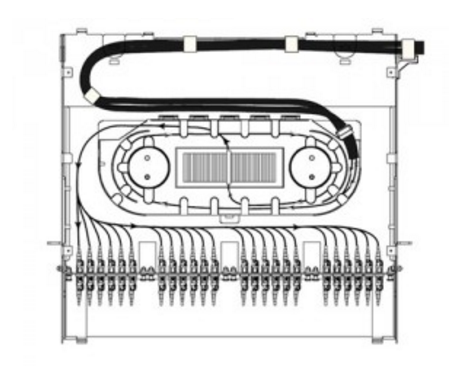

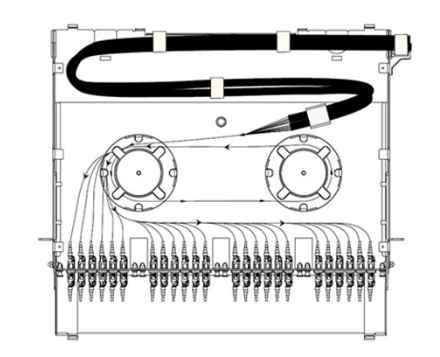

FHD-1UFMT-N is a 1U rack mount enclosure with an easy-to-move cover. That is to say, this rack mount fiber patch panel has a removable lid. You can remove its cover and then organize your cables with different solutions. It can hold up to 4 x fiber adapter panels or 4 x MTP/MPO cassettes of up to 96 fibers for cable management.

This FHD-1UFMT-N enclosure can provide you with multiple solutions on fiber optic patching, terminating and splicing applications. Here are the three main uses of this 1U rack mount enclosure:

1) It enables fiber splice tray installation and removement. In addition, one FHD-1UFMT-N enclosure can hold up to 4 splice trays.

2) It can hold up to 2 slack spools for cabling.

3) It supports high-density cabling management with up to 4 MTP or MPO cassettes.

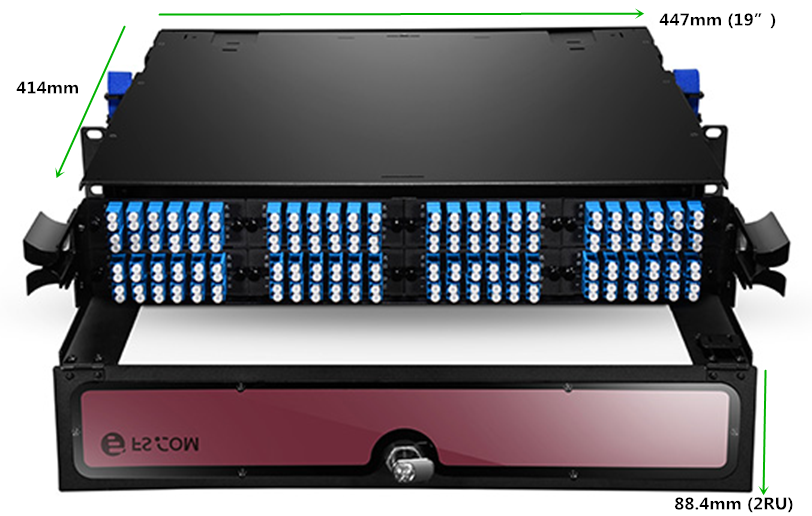

FS FHD-1UFCE 1U Rack Mount Enclosure

FHD-1UFCE enclosure is also one of the self-developed products provided by FS.COM. This 1U rack mount enclosure offers you easy and quick installation within its 1U space.

- Net Weight: 5.6KG

- Dimensions: 44mm(H) x 448mm(W) x 467.5mm(D)

- Material: Steel with black powder coating

- Modular Design: 4x FAPs or 4x HD MPO/MTP cassettes can be loaded, up to 96 fibers

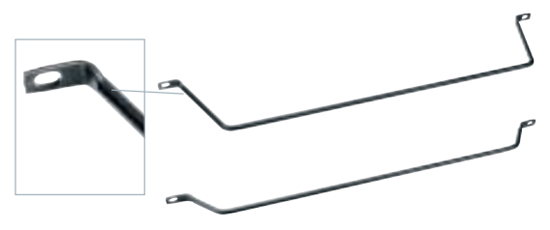

- Accessories: Mounting hardware and accessory kit with labels and bend radius bracket included

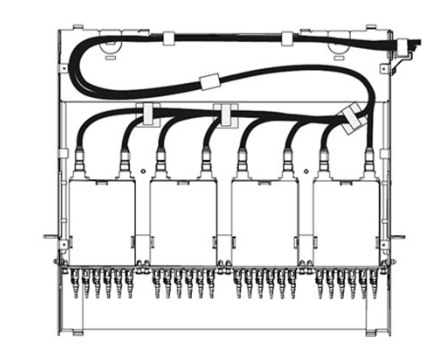

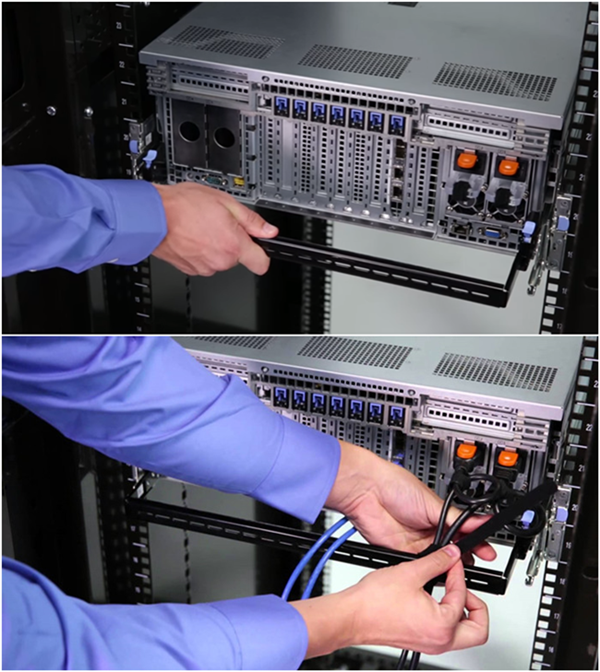

FHD-1UFCE is a 1U rack mount enclosure with a parallel sliding drawer. Compared with the normal design with removeable lid, this unique design saves your time and energy without removing the top cover whenever installation is needed. You can slide the drawer out and then install matching products to organize your cables with ease. It can hold up to 4 x fiber adapter panels or 4 x MTP/MPO cassettes of up to 96 fibers for cable management as well.

The main uses of this 1U rack mount enclosure are the same as FHD-1UFMT-N rack enclosure. The FHD-1UFCE supports patch cord connections with slack spools, storage of spliced fiber pigtails and cabling management with MTP or MPO cassettes as well.

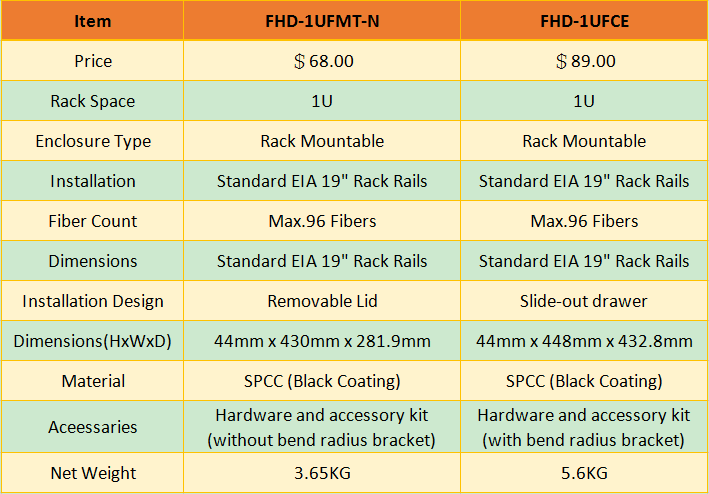

Buyer’s Guide: FHD-1UFMT-N vs FHD-1UFCE

Normally, these two styles (slide-out style and removable style) of enclosures have much in common. However, they still differ from each other.

Conclusion

For 1U rack mount enclosure choosing, you can take many factors into consideration. As for FHD-1UFMT-N vs FHD-1UFCE, the main applications are the same. They both can be used for patch cord connections, storage of spliced fiber pigtails and high-density MTP or MPO cabling management. Therefore, you can focus on their differences in price, installation design, dimensions, weight, etc. By the way, FS offers other rack mount enclosures such as 2U, 4U as well. You can choose a proper fiber enclosure according to your actual needs.

Related Articles:

High Density Rack Mount Fiber Patch Panel for Fiber Adapter Panels & MTP Cassettes