Fiber enclosure can provide easy-to-manage cabling environments and strong protection for fiber optic cables. Since more and more cables used in today’s data centers, high-density cable management tools also become more popular and essential than before. However, there are so many fiber enclosure manufacturers and suppliers, and the rack mount fiber enclosures supplied therefore available in different sizes and applications. How to choose the rack mount fiber enclosures for your network?

Rack Mount Enclosures Configurations

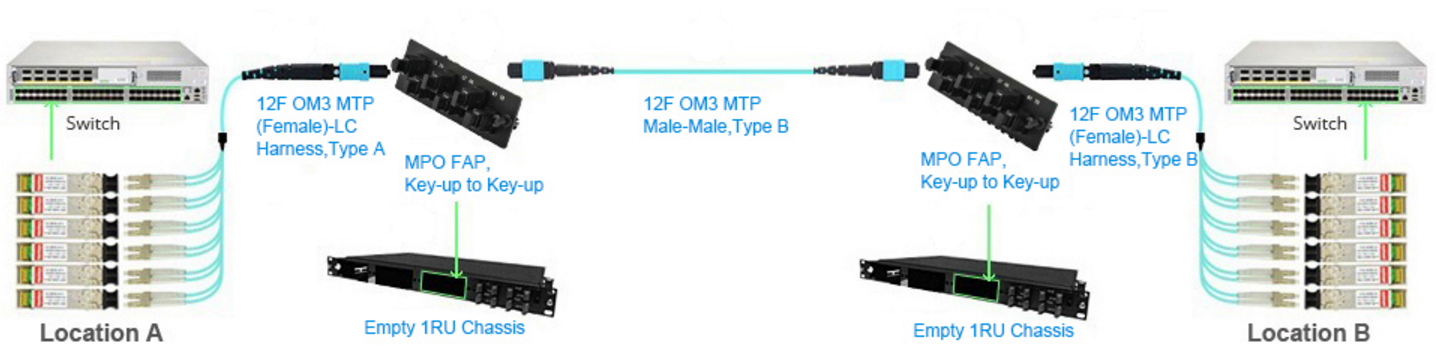

The rack mount enclosure is generally made for standard 19 inch rack mounting. Depending on the number of connections required, they are available in one or more rack units (RU) height configurations, such as 1RU, 2RU or 4RU, etc. See the picture below, you should choose the most proper one depending on space and port requirement of your network.

Rack Mount Enclosures Mount Types

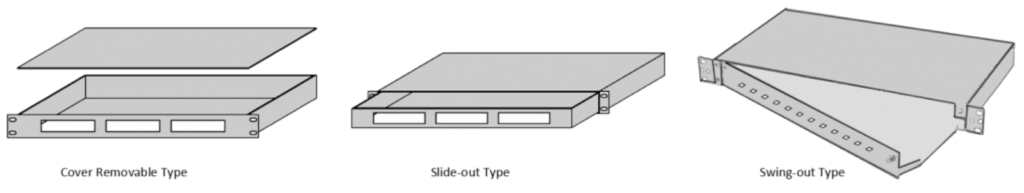

1RU rack mount fiber enclosures are the most commonly used size in data center server racks cable management. For convenient installation and cable management, there are cover removable, slide-out and swing-out three mount types fiber enclosures to choose from. The cover removable type is an early type of fiber enclosures. If your budget is sufficient, I will recommend you to use the slide-out type or swing-out type though they are more expensive than the cover removable type. But you may get more benefits during installation and maintenance, as they respectively feature a convenient slide-out support tray and an integrated swing-out tray so that you don’t need to remove the whole enclosure from the rack to gain internal access.

Rack Mount Fiber Enclosures Applications

Fiber enclosure has various designs and applications. There are mainly three ways to use the fiber enclosures, which are depended on the accessories that are installed on the fiber enclosure. The following will take a slide-out 1RU rack mount fiber enclosure as example to illustrate the applications of the fiber enclosures in data center. Installed with splice trays, fiber adapter panels and MTP cassettes separately, fiber enclosure can provide cabling environment for different connections.

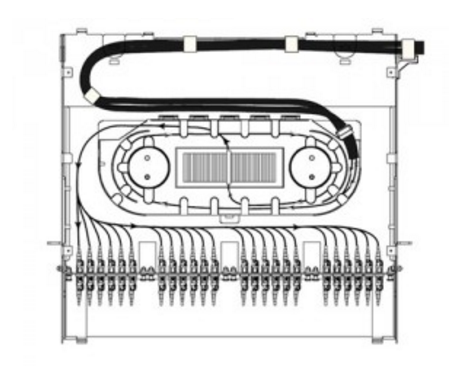

Application 1: Installing splice tray and FAPs

Installing four fiber adapter panels on the front panel and one or more splicing trays inside the enclosure drawer. This fiber enclosure can provide cable management and protection for splicing joints and connections.

Application 2: Installing Spools and FAPs

Installing two spools on the enclosure drawer and four FAPs on the front panel, this fiber enclosure can provide flexible high density cabling for fiber patch cables.

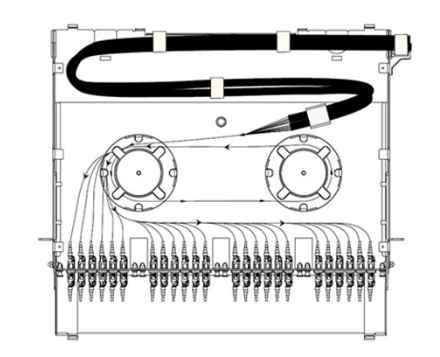

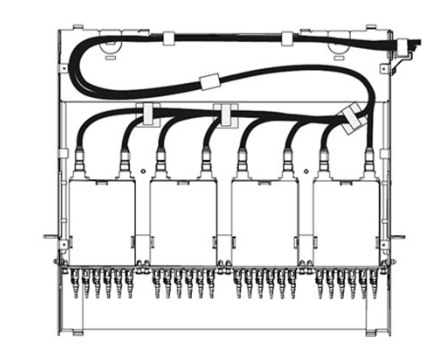

Application 3: Installing HD MTP Cassettes

Up to four MTP Cassettes can be installed in this 1U fiber enclosure, which can provide 40G/100G to 10G high cabling density and easy transferring from MTP interface to LC interface.

Conclusion

After reading the passage, we know that rack mount fiber enclosures may be available in different sizes, mount types and applications. Thus to choose a right fiber enclosure seems not a simple thing. FS.COM offers a wide range of rack mount enclosures, as well as custom service, which can help address all kinds of your requirements. For more details, please contact us via sales@fs.com or call 24/7 Customer Service: 1 (718) 577 1006.

Related Article: Upgrade to 40G / 100G Networks with High-Density Fiber Enclosures