More and more data centers are upgrading to 40G and beyond, which adds more floor space is an expensive, disruptive and sometimes un-affordable solution. Therefore, we should use high-density products to solve this problem. Then push-pull TAB fiber patch cables were conceived. This high-density patch cable provides improved accessibility, reduced installation costs and outstanding performance for today’s demanding high-density data center applications. In this article, some knowledge of push-pull TAB fiber patch cables will be provided.

Introduction to Push-Pull Tab Patch Cables

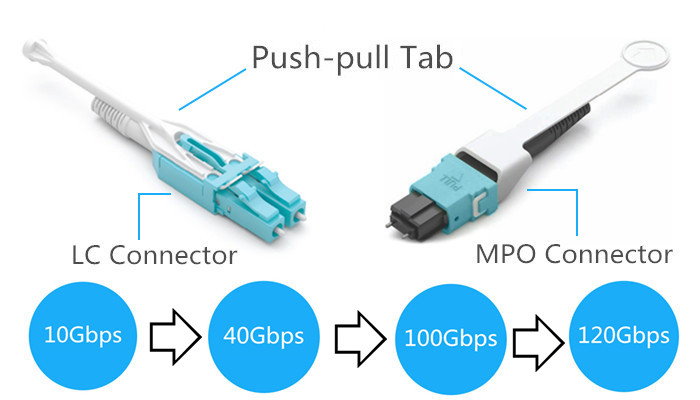

Push-pull TAB fiber patch cable is a new patch cord with a special “pull” tab design that can help to solve the problems of finger access in high-density cabling. It has the same components and internal-structure as the traditional patch cords, except a tab attached to the connector used for pushing or pulling the whole connector. With this special design, technicians can finish the installing and removing procedures with only one hand and no additional tools are needed. At present, this high-density push-pull TAB fiber patch cable, with either MPO or LC connector, is widely used in 40G and 100G network cabling.

Push-pull TAB fiber patch cable is a new patch cord with a special “pull” tab design that can help to solve the problems of finger access in high-density cabling. It has the same components and internal-structure as the traditional patch cords, except a tab attached to the connector used for pushing or pulling the whole connector. With this special design, technicians can finish the installing and removing procedures with only one hand and no additional tools are needed. At present, this high-density push-pull TAB fiber patch cable, with either MPO or LC connector, is widely used in 40G and 100G network cabling.

Types of Push-Pull Tab Patch Cables

There are mainly two kinds of push-pull TAB fiber patch cables in the market: LC-HD TAB fiber patch cables and MPO-HD TAB fiber patch cables. The LC-HD TAB fiber patch cable is designed for the LC-HD switchable& movable connector. And its slim uni-boot design saves much space and makes cables more easily to be managed. MPO-HD TAB fiber patch cables can greatly simplify the use of MPO connectivity when manual access to the release slider and rear portion of the connector is restricted. In this way, easy insertion and extraction of MPO patch cords can be achieved.

Advantages of Using Push-Pull Tab Patch Cables

Though traditional patch cables are popular in the data center, the push-pull TAB patch cables have many unique advantages.

- Easy to Release Patch Cord

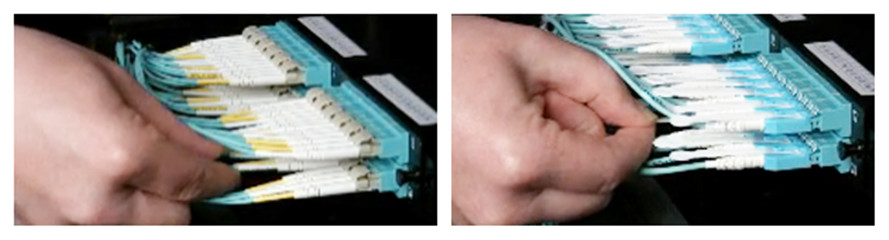

In high-density environment such as 48-port 1U patch panels, inserting and disconnecting patch cords can be challenging for technicians. The flexible pull-tab of the patch cable allows for the connector to be disengaged easily from loaded panels without the need for special tools. In fact, a gentle pull on the tab may disengage the connector from extremely dense fiber patch panels. Furthermore, labeling is also available on the pull-tab so that each cable can be quickly identified.

- Higher Flexibility and Adjustabilityfie

Push-pull patch cords are available in various specifications which can connect different generation of devices from 10Gb/s to 120Gbp/s or more. It provides safe and easy push and pull of the specific connector without affecting the other connectors around it. What’s more, high-density and ease of installation provide a low initial investment cost. All these benefits provide a high return on investment.

- Space Saving

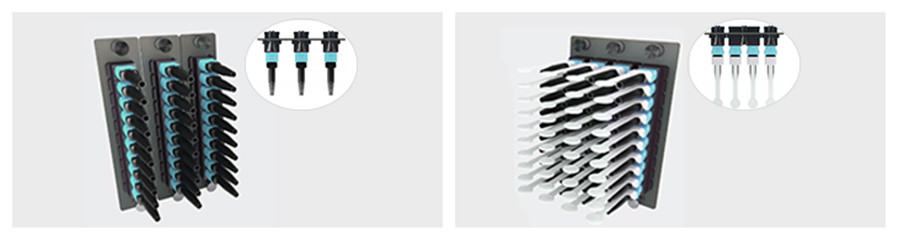

The traditional connectors often require a small vertical space above and below the adapters. While the low profile push-pull TAB patch cable, together with its pull tab, allow adapters to be stacked with absolutely no vertical space (as in the following figure).

Conclusion

We started with 1G switches. Those switches became 10G. Recently we’ve seen the trend of 40G. In the future, those switches will become 100G and even 120G. It has been proved that push-pull tab patch cords can support high durability and flexibility which fit the connection between devices of different data rate. Fiberstore offers a wide range of push-pull TAB patch cables that will help free up space.We supply simplex&duplex LC-HD patch cords, 12&24 fibers MPO-HD patch cords, MPO-LC harness cables, providing low-loss performance for multi-mode and single mode high speed networks and improving network performance.