Overview of Fiber Optic Enclosures

Just like copper-based cabling systems, fiber-optic cabling systems have a few specialized components, including fiber optic enclosures and connectors.

Because laser light is dangerous, the ends of every fiber-optic cable must be encased in some kind of fiber optic enclosure. The fiber optic enclosure not only protects humans from laser light but also protects the fiber from damage. Wall plates and patch panels are the two main types of fiber optic enclosures. We’ll discuss patch panels here.

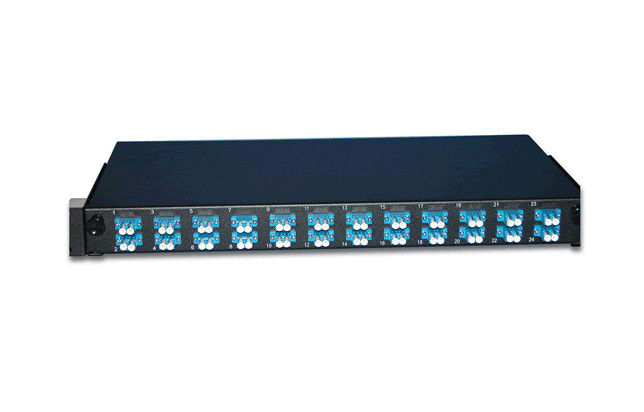

When most people think about a fiber optic enclosure, a fiber patch panel comes to mind. It allows connections between different devices to be made and broken at the will of the network administrator. Basically, a bunch of fiber-optic cables will terminate in a patch panel. Then, short fiber-optic patch or interconnect cables are used to make connections between the various cables. There are dust caps on all the fiber-optic ports, which can prevent dust from getting into the connector and interfering with a proper connection.

Types of Fiber Optic Enclosures

Patch panels come in many shapes and sizes. Some are mounted on a wall and are known as surface-mount patch panels. Others are mounted in a rack and are called rack mount patch panels. Each type has its own benefits. Surface mount panels are cheaper and easier to work with, but they can’t hold as many cables and ports. Surface-mount patch panels make good choices for smaller (fewer than 50 drops) cabling installation. Rack-mount panels are more flexible, but they are more expensive. Rack mount patch panels make better choices for larger installations. Patch panels are the main products used in LAN installations today because they are extremely cost-effective and allow great flexibility when connecting workstations.

In addition to the standard fiber patch panels, a fiber-optic installation may have one or more fiber distribution panels, which are very similar to patch panels in that many cables interconnect them. However, in a distribution panel, the connections are more permanent. Distributions panels usually have a lock and key to prevent end users from making unauthorized changes. Generally speaking, a patch panel is found wherever fiber optic equipment hubs, switches, and routers are found. Distribution panels are found wherever multifiber cables are split out into individual cables. Here is the example of 24 port patch panel.

Our wall mounted fiber optic enclosures accommodate up to 8 modular panels and is equipped with routing guides to limit bend radius and enhance strain-relief control. The 16-gauge steel with corrosion-resistant black powder finish coat housing provides excellent protection for the inside fibers. Wall-mount available unloaded, as well as having the capability to become a full-splice enclosure with mechanical terminations. A large variety of connector adapters are offered to meet your specific requirements. Such as SC, FC, ST, LC, etc, we can also pre-install various kinds of fiber optic pigtails inside the patch panel. We offer a series of changeable inside panels to fit for different kinds of the adaptor interface, and fit for both round and ribbon fiber optic cables.