What Is Armored Fiber Cable?

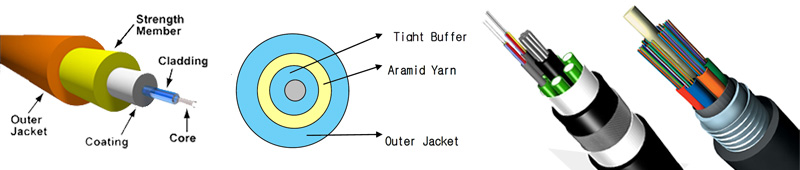

Armored fiber optic cable consists of a cable surrounded by a steel or aluminum jacket which is then covered with a polyethylence jacket to protect it from moisture and abrasion. It may be run aerially, installed in ducts, or placed in underground enclosures with special protection from dirt and clay intrusion.

Armored fiber optic cable is often installed in a network for added mechanical protection. Two armored fiber cable types exist: interlocking and corrugated. Interlocking armor is an aluminum armor that is helically wrapped around the cable and found in indoor and indoor/outdoor cables. It offers ruggedness and superior crush resistance. Corrugated armor is a coated steel tape folded around the cable longitudinally. It is found in outdoor cables and offers extra mechanical and rodent protection.

Types Of Armored Fiber Cable

Armored fiber cable can be divided into indoor armored fiber cable and outdoor armored fiber cable. With the fast development of fiber optic communication technology and the trend of FTTX, indoor fiber optic cables are more and more required to be installed between and inside buildings. Typical indoor armored fiber cable types include GJFJV, GJFJZY, GJFJBV, GJFJBZY, GJFDBV and GJFDBZY. Compared with outdoor use fiber cable, indoor fiber cable experiences less temperature and mechanical stress, but they have to be fire retardant, emit a low level of smoke in case of burning. And indoor armored fiber optic cable allows a small bend radius to make them be amendable to vertical installation and handle easily.

Features of Indoor Armored Fiber Cable

* Good mechanical property and environment property.

* Soft, agility, convenience for connect.

* Flexible and Easy to Handle

* Cables with Improved Attenuation Available

* Adapt to harsh environments and man-made damage.

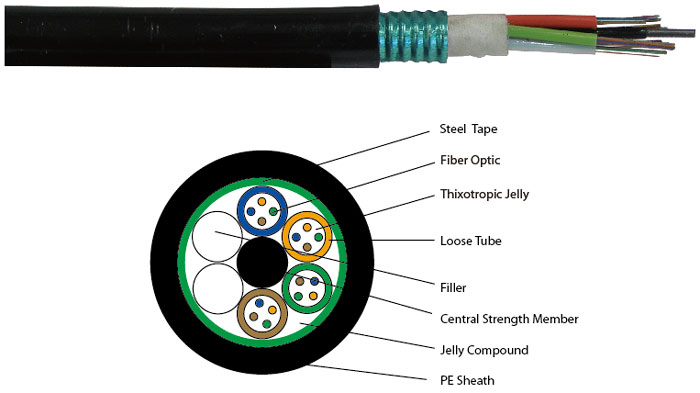

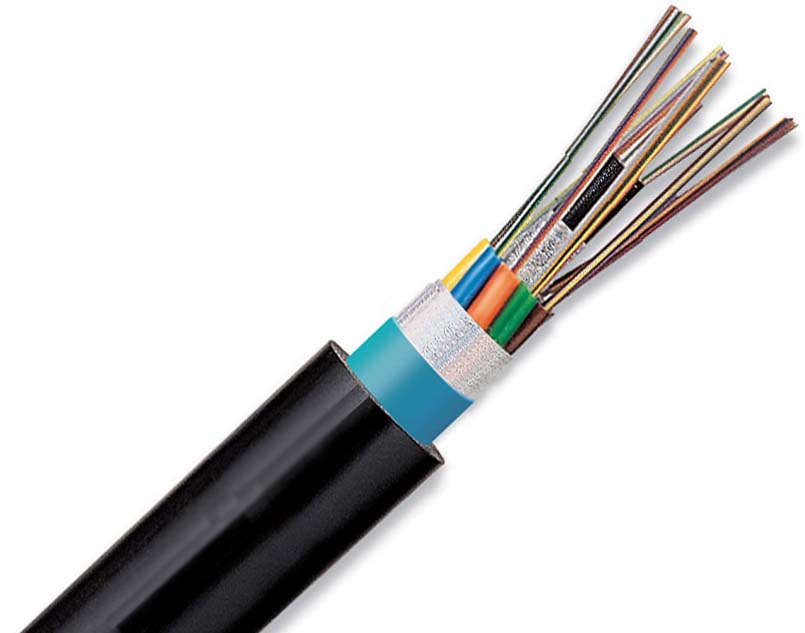

Outdoor armored fiber cable is made to protect the optical fiber to operate safely in complicated outdoor environment. Most Outdoor Armored fiber cables are loose buffer design, with the strengthen member in the middle of the whole cable, the loose tubes surround the central strength member. Inside the loose tube there is waterproof gel filled, whole cable materials used and gels inside cable between the different components (not only inside loose tube) will help make the whole cable resist of water.

Features

* Excellent attenuation performance

* Dry water blocking for moisture protection

* Polyethylene jacket for weather and UV protection

* Breakout kits available

* Corrugated Steel Tape

* Rodent Resistant

* Waterblock gel available

Application of Armored Fiber Cable

Armored fiber cable is used in direct buried outside plant applications where a rugged cable is needed and/or for rodent resistance. Armored fiber optic cable withstands crush loads well, for example in rocky soil, often necessary for direct burial applications. Cable installed by direct burial in areas where rodents are a problem usually have metal armoring between two jackets to prevent rodent penetration. Another application for armored fiber cable is in data centers, where cables are installed under the floor and one worries about the fiber cable being crushed. Indoor armored fiber optic cables may have nonmetallic armor. Metallic armored fiber cable is conductive, so it must be grounded properly. As with other fiber optic components, there are different names or meanings used. “Armor” in some companies’ jargon denotes a twisted heavy wire rope type cable surrounding the entire poly cable sheath/jacket. Single or double armor (two opposite ply layers of the steel wire) is typically used underwater near shore and shoals. Inner metallic sheath members of aluminum and/or copper are used for strength and for buried cable locating with a tone set.

Related Article: https://community.fs.com/blog/what-is-armored-fiber-optic-cable.html