Indoor/outdoor fiber optic cables include loose tube and tight buffer designs. These are available in a variety of configurations and jacket types to cover riser and plenum requirements for indoor cable and the ability to be run in duct, direct buried or aerial/lashed in the outside plant. Applications of tight-buffered distribution cable will be provided in this article. This blog provides information on tight-buffered distribution cable’s basic sense and its indoor and outdoor applications.

Construction of Tight-Buffered Distribution Cable

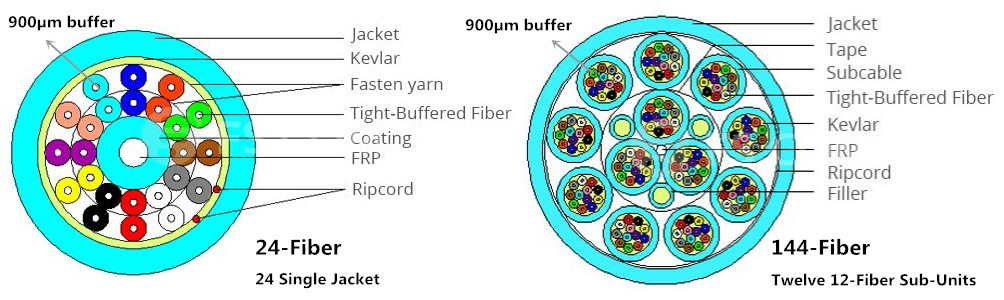

Standard tight-buffered distribution cable is available in fiber counts from 6 to 144 fibers. Distribution cable in 6, 12, and 24-fiber counts in a “single jacket” designs feature 900µm tight-buffered fibers surrounded by an aramid yarn strength member. Larger distribution cable (36 fibers and greater) features a “sub-unit” design that simplifies fiber identification, provides easy access and routing of the fibers and increases cable durability with a dielectric central strength member. For example, a 144-fiber cable usually has twelve 12-fiber sub-units while a 36-fiber cable could have six 6-fiber sub-units or three 12-fiber sub-units.

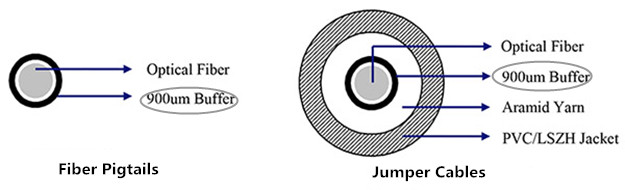

900µm Buffer for Easy Fiber Termination

Tight-buffered distribution cable can be directly connected to optical equipment for the fibers normally have a 900µm buffer. Terminated fibers may be directly connected to equipment without use of a patch panel and accompanying jumper cables. Besides, no splices or splicing skills are needed, as with pigtails on loose tube gel-filled cables. In situations where the fibers will be mated and unmated frequently, or where there is general access to equipment, it is advisable to place terminated fibers in a patch panel to avoid damage to the connector/fiber interface.

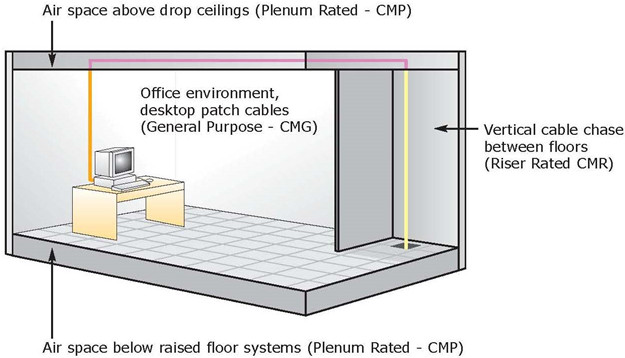

Plenum/Riser Tight-Buffered Distribution Cable for Indoor Applications

Fiber optic tight-buffered distribution cable is used within buildings to provide high-density connectivity and ease of installation. Applications include intra-building backbones, routing between telecommunications rooms and connectorized cables in riser and plenum environments. For trunking applications where fiber distribution cable is being run through environmental airflow spaces, we should plenum tight-buffered distribution cable. It is in compliance with NEC section 770.179(a) for installation in plenums and air ducts. In vertical runs, as shown in the figure below, we usually use riser tight-buffered distribution cable.

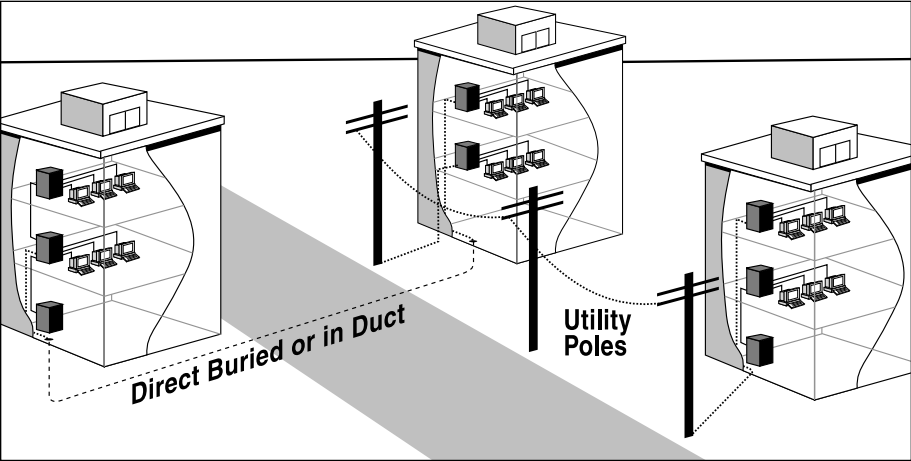

Armored LSZH Tight-Buffered Distribution Cable for Indoor/Outdoor Applications

Armored LSZH tight-buffered distribution cable features a double LSZH jackets with the outer jacket being of UV stabilised, water and moisture resistant. Between the 2 sheaths there is a corrugated steel tape making the cable rodent proof. The cable is suited for LAN backbones, direct burial, ducts, under floor or ceiling spaces.

Conclusion

The tight-buffered design provides a rugged cable structure to protect individual fibers during handling, routing and connectorization. Yarn strength members keep the tensile load away from the fiber. Multi-fiber, tight-buffered cables often are used for intra-building, risers, general building and plenum applications. FS.COM offers a wide range options on high-quality tight-buffered distribution cables which can meet your demands on indoor or indoor/outdoor applications. Same-day shipping from USA is available. For more information, please visit www.fs.com.

Related Article: Tight-Buffered Fiber Distribution Cable for Indoor and Outdoor Use