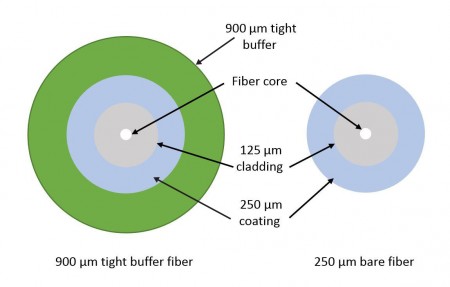

Ever wonder the difference between loose-tube 250um bare fiber and tight-buffered 900um fiber? Loose-tube 250um and tight-buffered 900um fiber cables actually start with the same 250um bare fibers that feature the same size fiber core (i.e., 50um for multimode and 9um for singlemode), 125um cladding and soft 250um coating. The difference between these two cables all lies in the cable construction.

900um Fiber Adds an Additional Layer

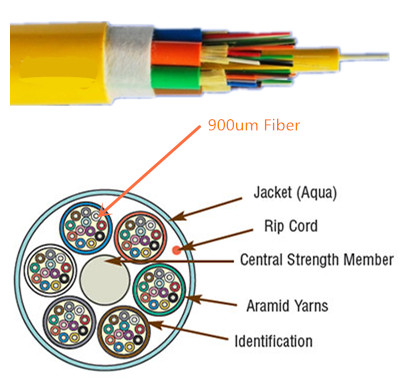

Tight-buffered 900um fiber includes an additional 900um layer of hard plastic over the 250um fibers for protection. Within the cable, several of these color-coded 900um tight buffered fibers are situated around a central strength member and then covered with Kevlar or aramid yarn for protection, a rip cord and then the jacket.

Tight-buffered 900um fiber cable comes in various fiber counts that typically range from 2 to 144 fibers, with larger fiber counts featuring fiber subunits of 6 or 12 fibers within the cable. For example, a 144-fiber cable usually has twelve 12-fiber subunits while a 36-fiber cable could have six 6-fiber subunits or three 12-fiber subunits.

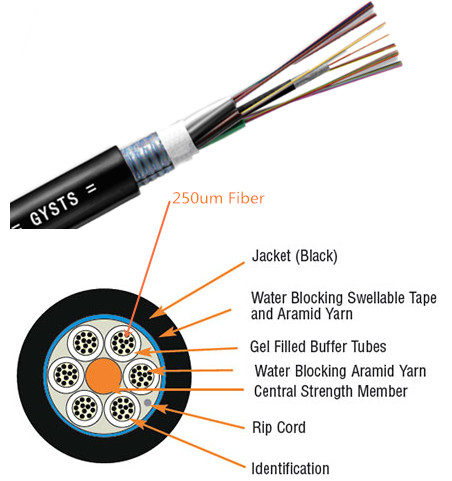

250um Fiber Is Enclosed in Tubes

Loose-tube 250um fiber places up to 12 bare 250um fibers inside a flexible plastic tube, which are also color coded and situated around a central strength member with Kevlar or aramid yarn for protection. Buffered loose-tube cables feature an outer waterblocking tape around the tubes, beneath the outer jacket.

The tubes themselves are gel-filled to prevent water migration, or they are available with a dry waterblocking technology—sometimes referred to as gel-free cable. Both of these materials are vital to prevent water from migrating into the tubes and potentially freezing, expanding and breaking the fiber. Dry waterblocking technology significantly reduces installation time by eliminating the need to clean off the gel prior to termination.

The tubes themselves are gel-filled to prevent water migration, or they are available with a dry waterblocking technology—sometimes referred to as gel-free cable. Both of these materials are vital to prevent water from migrating into the tubes and potentially freezing, expanding and breaking the fiber. Dry waterblocking technology significantly reduces installation time by eliminating the need to clean off the gel prior to termination.

Loose-tube 250um fiber cable comes in various fiber counts that typically range from 6 to 144. With the exception of a 6-fiber cable, the fibers are grouped into sets of 12 for maximum density. Speaking of density, without the 900um plastic coating, loose-tube 250um fiber cables are less than half the size of 900um fiber cables—1.4 inch (35.6 mm) for a 144-fiber tight buffer cable and only 67 inch (17 mm) for an outdoor 144-fiber loose-tube cable.

From Outdoor to Indoor Applications

Generally speaking, tight-buffered 900um fiber cables are used for indoor applications, including intra-building riser and plenum applications and in the data center. Loose-tube 250um fiber cables are typically used in outside plant (OSP) applications, such as inter-building duct, aerial and direct buried installations.

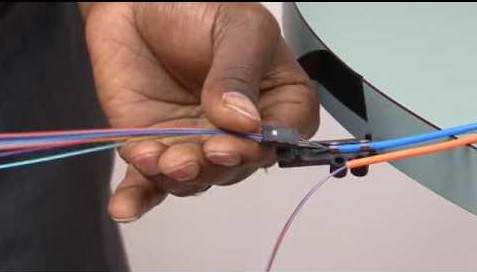

While indoor/outdoor cables are popular for eliminating the need for service entrance splicing to in-building cable, OSP loose-tube 250um cabling must be terminated within 50 feet of entering a facility. To accomplish this, breakout kits are used to build the 250um cable up for protection and termination to 900um connector boots. The problem with breakout kits is that they add additional material costs and a significant amount of labor. One option is to terminate the 250um fiber directly to 250um connector boots. This can speed network deployment in the data center and fiber-to-the-home applications.

While indoor/outdoor cables are popular for eliminating the need for service entrance splicing to in-building cable, OSP loose-tube 250um cabling must be terminated within 50 feet of entering a facility. To accomplish this, breakout kits are used to build the 250um cable up for protection and termination to 900um connector boots. The problem with breakout kits is that they add additional material costs and a significant amount of labor. One option is to terminate the 250um fiber directly to 250um connector boots. This can speed network deployment in the data center and fiber-to-the-home applications.