Increased demand for data to support streaming media and the increased use of mobile broadband communications has resulted in dramatic advances in network switching infrastructure over the past 10 years. Furthermore, this demand is expected to continue at a record pace. Since the transition from copper to fiber as the standard for high-performance data communications and the number of fibers used to support emerging standards, such as 100GBit/s Ethernet, for the individual connection has increased, to choose higher density fiber optic enclosures is certainly innate.

Currently, network switching products are available with port line cards that use more than 1,000 OM3 fiber and OM4 fibers per chassis switch for 10G duplex fiber applications. Future 40/100Gb switches are projected to use more than 4,000 fibers per chassis where parallel optics is used. These high fiber count requirements demand high-density cable and hardware solutions that will reduce the overall footprint and simplify cable management and connections to the electronics.

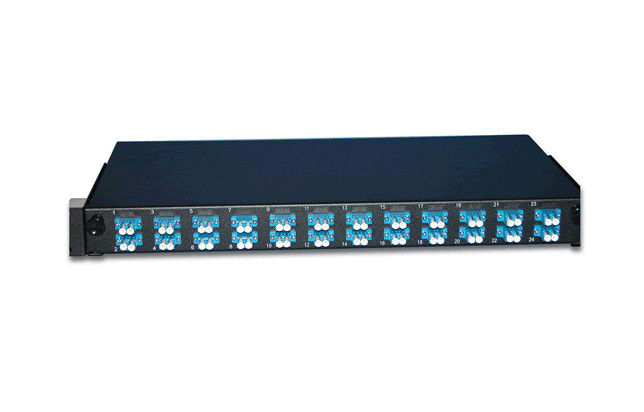

Fiberstore’s new FMT1-4FAP-LCDX series product allows customers to migrate from a standard 2U fiber enclosure that will house 3 adapter panels for a maximum of 72 LC connectors to our new 96 ports fiber optic enclosures that will hold 4 adapter panels in a 1U space allowing a maximum of 96 LC connectors! This gives users 33% (or 24 more) more LC connections in a 1U enclosure versus a 2U enclosure.

Besides, you can get more density by utilizing our MPO/MTP to LC cassette module. Our HDSM-12MTP/MPO rack mountable MTP cassette is loaded with 72 LC duplex connectors, giving it 144 ports total within 1U of rack space. And this 1U enclosures can be mounted vertically so you can match every blade in the switch to each enclosure. This high-density MTP cassette is constructed of light weight, yet durable, rolled steel. The shallow depth of the Ultra Panel makes it suitable for copper racking systems or telecommunication rack infrastructure.

With the rise in demand for higher bandwidth and faster download speeds, FS.COM high-density fiber optic enclosures were designed to keep pace with these requirements. In addition, both of these unique fiber optic enclosure lines offer installers easy terminations, and performance-driven connectivity. Couple that with FS.COM’s proven fiber optic cable, in particular, our HD push-pull tab patch cables, customers can expect an exceptional solution to fit their high-density needs.